Integrated Type Electromagnetic Flow Meter

Product Instructions

Working principle of electromagnetic flowmeter measurement principle is based on the Faraday law of electromagnetic induction. Measurements of the flow meter tube is lined with insulating material of a non-magnetic alloy spool. Two clicks along the diameter through-wall fixing on the measuring tube. The electrode head is flush with the lining inner surface. Field coil by waves when pulsed excitation by both parties, will be measured perpendicular to the pipe axis direction produces a magnetic flux density of the magnetic field b. At this point, if you have some electrical conductivity of fluid flows through the measuring tube, cut magnetic lines of induction electromotive force E. Electromotive force e is proportional to the magnetic flux density B, measure the inside diameter d and the product of the mean velocity v. Electromotive force e (traffic signal) checked out by electrodes and cables to the converter. Converter after the traffic signal will be amplified, to display fluid flow and energy output pulse, analog current signals for flow control and the flow adjustment.

Product Features

1. No moving and blocked flow parts in the pipeline, almost no additional pressure loss in the measurement.

2. Measurements results are independent of physical parameters, such as flow distribution, fluid pressure, temperature, density and viscosity.

3. LCD display, easy to use and simple to operate.

4. Magnetic flow meter use SMD devices and SMT technology.

5. Self-checking function.

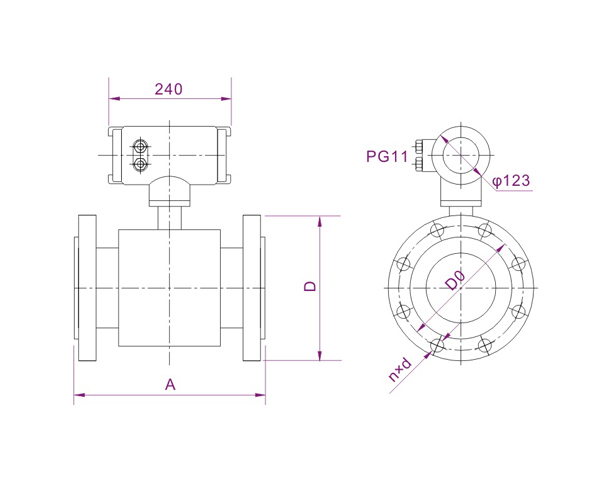

Product Structure

Technical Parameters

Series of nominal diameters DN (mm)

| PTFE Lined Pipe | 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 450, 500, 600 |

| Rubber Lined Pipe | 40, 50, 65, 80, 100, 125, 150, 200, 300, 350, 400, 500, 600, 800, 1000, 1200, note: special specifications can be customized |

| Measuring range ratio | 150:1 |

| Repeatability error | +/-0.1% |

| Accuracy | Piped: 0.5 class, 1.0 class |

| Measured medium temperature | Common rubber lining: -20~+60 ° c |

| High temperature rubber lining: -20~+90 ° c | |

| PTFE lining: -30~+100 ° c | |

| High temperature vinyl lining: -30~+180 ° c | |

| Rated working pressure | Pipeline: DN10~DN65: ≤ 2.5MPa;DN80~DN150: ≤ 1.6MPa;

DN200~DN1200: ≤ 1.0MPa |

| Flow measuring range | Flow measuring range corresponding to flow rate range is 0.3~15m/s |

| Measured fluid conductivity | 5μs/cm (Most with water as the composition of the medium, its conductivity in the range 200~800 Mu s/cm, optional solenoid flow) |

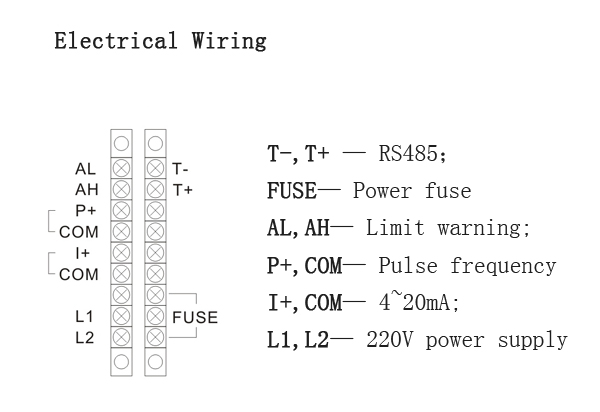

| Output | Current:4~20mADC (isolation), pulse frequency 0~1kHz, OCT photoelectric isolation, external power ≤ 35VDC, breakover, collector Max 25mA |

| Electrode material | 316L, titanium (Ti), tantalum (Ta), Hastelloy, (h), Platinum (Pt) or other special electrode materials |

Product Applications

Due to its unique advantages, the electromagnetic flow meter is widely used in the fields of petroleum, chemical industry, steel, light industry, sewage processing, environmental protection, water conservancy project and pharmacy to measure the volume flow of the conducted liquid mediums, such as acid, alkali, salt solution and so on.