【Abstract】According to the feedback of the internal debris residue problem in the use of the magnetic flip column level gauge, the series of measures for the magnetic flip column level gauge to prevent debris and deposition problems are briefly described, and the working principles of various measures are introduced. , optimized implementation and how the magnetic flip column level gauge can achieve self-cleaning. I. Foreword The concept of sponge city was first proposed in the 2012 Low-Carbon City and Regional Development Science and Technology Forum, and then the General Office of the State Council issued the “Guiding Opinions on Promoting the Construction of Sponge City”, which pointed out that the use of infiltration, stagnation, storage, purification, utilization and discharge and other measures, in which the application of pumping stations is essential, and the advantages of prefabricated pumping stations will become the first choice for municipal drainage systems. As an alternative to small and medium-sized concrete pumping stations, deposition inside the pumping station is an important problem. The common problems of traditional pumping stations are that the accumulation of debris in the pit and the sedimentation at the bottom of the pit need to be treated regularly. The long-term accumulation of garbage ferments and smells, causing the deterioration of the surrounding environment, and even producing toxic, flammable and explosive gases, which endanger the surrounding environment.

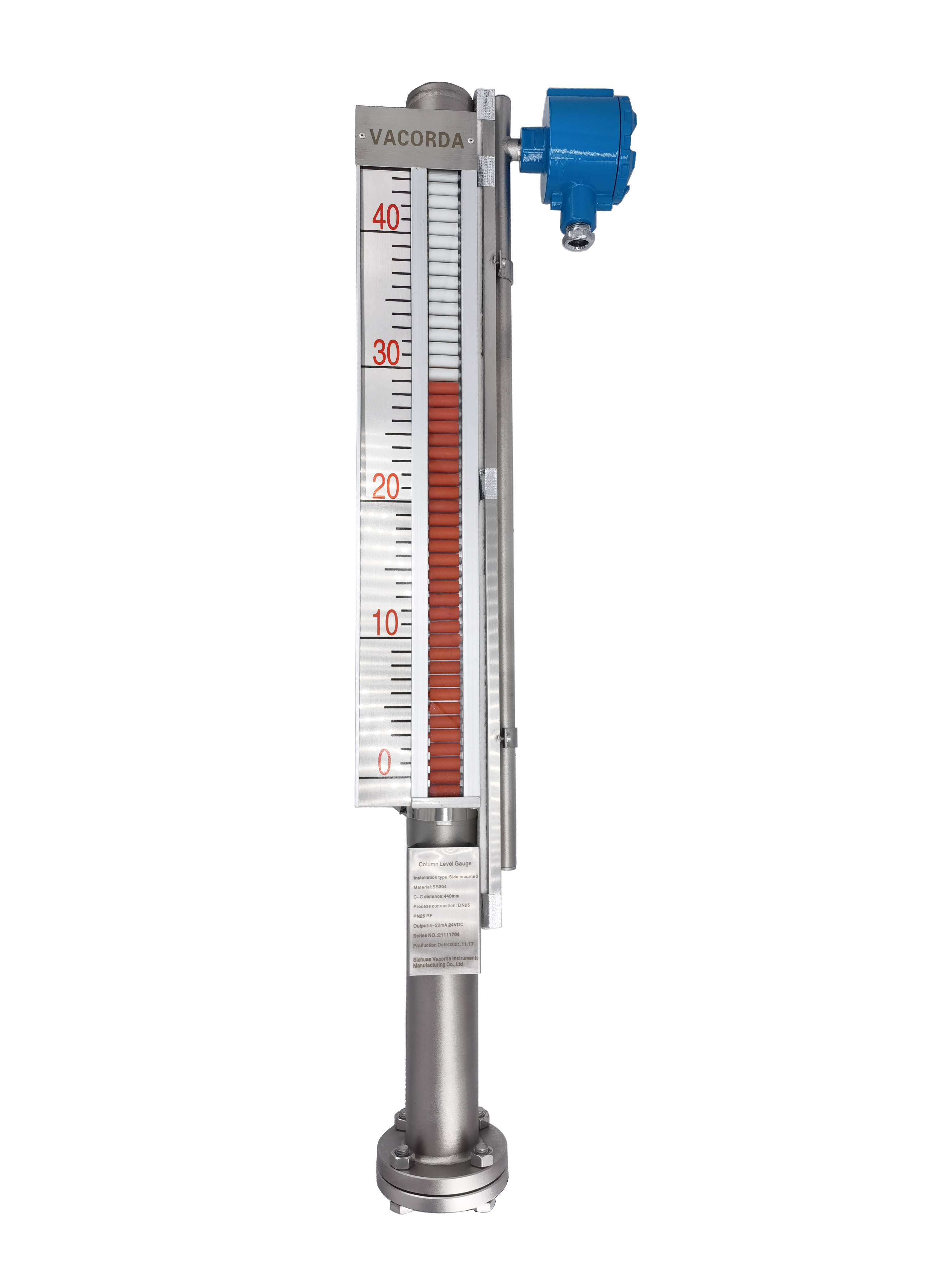

While optimizing the volume, the magnetic flip column liquid level gauge proposes a self-cleaning solution from the pump station to solve the problem of debris residue inside the magnetic flip column liquid level gauge and wellbore deposition. In view of the above problems, taking the two aspects of debris treatment and cleaning up deposition as breakthrough points, according to the working principle of the magnetic flip column liquid level gauge, combined with the design work experience of the magnetic flip column liquid level gauge, a brief introduction to its structure, configuration, etc. The self-cleaning function of the magnetic flip column level gauge. The simple model of the magnetic flip column level gauge is shown in Figure 1.

2. Debris treatment

1. Grille device The structure of the magnetic flip column level gauge is shown. After the inlet flange of the magnetic flip column level gauge, set the first interception measure, that is, the grille device. As a highly integrated and automated product, pulverized grids are often used in current projects. The pulverized grids have the functions of small footprint and convenient use, which can cut and pulverize the impurities entering the pump station at the first time. The crushing grid can crush the suspended solids and floating garbage in the sewage into fine particles of 6~10mm. The crushed small particles of impurities do not need to be salvaged and can be directly discharged through the submersible sewage pump. From an economic point of view, a basket-type grill can be selected, which is characterized by the need to regularly lift the grill from the pump station to clean up the debris intercepted in the grill, with a simple structure and low cost. Compared with the crushing grille, the basket grille has a larger grille, and the effect of intercepting impurities is not very good. The grille device intercepts and processes large or band-shaped impurities at the entrance of the pump station at the first time, so as to prevent large impurities from entering the pump

There will be debris accumulation inside the station, which is the first level for the prevention of deposition.

2. Pump configuration

Equipped with a cutting-type submersible sewage pump for the magnetic flip column liquid level gauge, it can easily crush the fibers entrained in the sewage. After being filtered by the grid, the larger debris is processed, and the medium entering the pump station may still contain some debris (such as ribbon fibers, plastics, etc.). The cutting type submersible sewage pump is provided with a The rotating cutter head and the stationary cutter head structure, under the high-speed rotation of the cutter head, the long fibers in the sewage are cut and crushed by the cutter head on the back of the cutter head, and the crushed residue is sucked by the impeller and discharged from the pump station through the pump outlet.

3. Clean up the silt

1. Wellbore self-cleaning structure The bottom of the cylinder of the magnetic flip column level gauge is an intelligent concave structure specially designed by CFD. This unique hydraulic design structure can ensure that the wellbore can resist the pressure of groundwater without deformation. When the pump is started, the slope structure of the pump pit makes the medium in the pump pit reach a high flow rate, thereby generating a strong eddy current. On the one hand, the bottom water flow is concentrated to the pump inlet, so that the crushed debris can be better transported by the pump; On the other hand, it drives the movement of the impurities precipitated at the bottom of the magnetic flip column level gauge to avoid siltation and make the precipitated solids re-suspend and enter the pump inlet, which can achieve the effect of self-cleaning.

2. Backwashing device Keep the external structure of the magnetic flip-up liquid level gauge unchanged, and optimize the design of the pipeline structure of the magnetic flip-up liquid level gauge in view of the deposition problem during the use of the magnetic flip-up liquid level gauge, as shown. A bypass pipeline structure is added to the main line of the pump outlet inside the magnetic flip column level gauge. The added bypass pipeline is one or more smaller diameter pipelines, and the outlet of the small diameter pipeline is aligned with the magnetic flip. Column level gauge is the position where siltation is likely to occur inside the wellbore. There is an electric valve between the bypass pipeline and the main pipeline, and the electrical control of the valve is connected to the control cabinet system of the magnetic flip column level gauge, which is related to the control of the water pump. When the water pump in the magnetic flip-column level gauge starts, the electric valve on the bypass pipeline is opened through the set control program, and part of the pressure water in the main outlet pipeline flows through the bypass pipeline. It is small, so that the outflowing pressure water becomes a high-speed water flow, and the high-speed water flow is aimed at the places where the liquid level gauge is easily deposited inside the wellbore, so that the impurities deposited in the magnetic flip column level gauge will follow the water pump under the re-impact of the water flow. It is transported to the outside of the magnetic flip column level gauge for discharge. According to the specific operating conditions of the magnetic flip column liquid level gauge, the opening and closing of the electric valve and the opening and opening interval can be intelligently adjusted in the control system.

3. Liquid level control

When the pumping station is in the dry season, after the liquid level drops to the minimum set minimum water level, because there is no liquid flow into the pumping station during the dry season, the liquid level will not rise to the normal pumping position, and the long-term pump stop period will lead to magnetic flipping. The impurities in the sewage in the wellbore of the column level gauge are gradually precipitated, adsorbed, and even agglomerated after the water vapor evaporates. This will result in the sediments not being able to drain out of the pumping station at all after the pumping station is started up again.

In response to this problem, the magnetic flip column liquid level gauge control system is set. When the system determines that the pump has been shut down for a long time, it will start the dry season mode: the control system closes the main valve of the pump station outlet, and opens the electric valve in the backwashing device. Control the pump to run for a short period of time after a period of time (for example, every 6 hours, the pump starts to run for 2 minutes) to ensure that the sewage inside the pump station does not deposit until the pump station is fully started next time.

4. Conclusion For the treatment of common solid impurities and their deposition problems in the magnetic flip-column liquid level gauge, the above method has proved its effectiveness in actual production and has been recognized by users.

However, for another kind of pollution inside the magnetic flip column level gauge: oil pollution and floating garbage, according to user feedback, the above measures cannot be effectively solved. For the optimization of domestic magnetic flip-column level gauges, unremitting efforts are needed.

Post time: 11-01-22