1. ScopeAlthough the range of the orifice flowmeter is very narrow (approximately: 1(4:1)), in recent years, from the adoption of a wide range of differential pressure transmitters, the parallel use of multiple differential pressure transmitters, and the replaceable orifice The adoption of plate throttling devices and the adoption of intelligent flow monitors have taken countermeasures to expand the range, but the range of gas ultrasonic flowmeters can reach 40:1 (dn150)-160:L dn75O ), in actual use The lower limit value of the flow rate that can be measured by the medium flowmeter is more important. The large-diameter gas pipeline system in China is generally in the low flow rate range (the upper limit value of the flow rate is 5, and the lower limit flow rate deviation of the ultrasonic flowmeter.The data shows that in the natural gas pipeline gas metering station, there is a metering station with an orifice flowmeter as the measuring instrument. In order to meet the requirements of the range, 4 dn400mm pipelines need to be set up. Adopt gas ultrasonic flowmeter, only need to set up two dn600mm lines or one dn700 line, adopting gas ultrasonic flowmeter can save 10, 40% of investment at one time, save 50, 75% of installation space, and have higher accuracy2. Pressure lossAs we all know, the pressure loss of the orifice flowmeter is very large, but the gas ultrasonic flowmeter is a kind of instrument with no pressure loss (equivalent to the first-level pipeline). In the case of a large diameter, this feature is very important and can save energy. It is also suitable for measuring low-pressure gas pipeline systems.3. The cost of the instrumentAs the diameter of the orifice flowmeter increases, the cost and installation cost of the detector rises sharply, but the relationship between the manufacturing cost and the diameter of the gas ultrasonic flowmeter detector is equivalent to the increase in the value of the pipeline, so it is especially suitable for large diameters instrument.4. Use and maintenanceThe orifice flowmeter consists of three parts, consisting of a throttling device, a differential pressure transmitter, and a flow indicator. The use of throttling devices, differential pressure transmitters and the pressure introduction pipelines of their connecting parts under harsh working conditions on site is the focus of maintenance. In order to frequently check the quality of the orifices of natural gas pipelines, the gas metering station needs to add a bypass pipe. Or the use of expensive replaceable throttling device gas ultrasonic flowmeter detector is relatively sturdy, the maintenance workload is small, and the plug-in probe can be taken out for maintenance under the condition of continuous flow.Compare the application of gas ultrasonic flowmeter and orifice flowmeter in the natural gas industry. In summary, gas ultrasonic flowmeter is undoubtedly superior in large-caliber measurement. Especially in the measurement of raw gas, the orifice flowmeter may solve the problem that has not been solved for many years. The current work in this area has been initially introduced, but it should be seen that the orifice flowmeter has a history of decades or even hundreds of years. Flow practitioners all over the world have carried out huge theoretical and practical work on it. Compared with the extremely rich experience, the gas ultrasonic flowmeter has just emerged, and it needs to mature through practice. There are more in small and medium calibers. Work to be done.

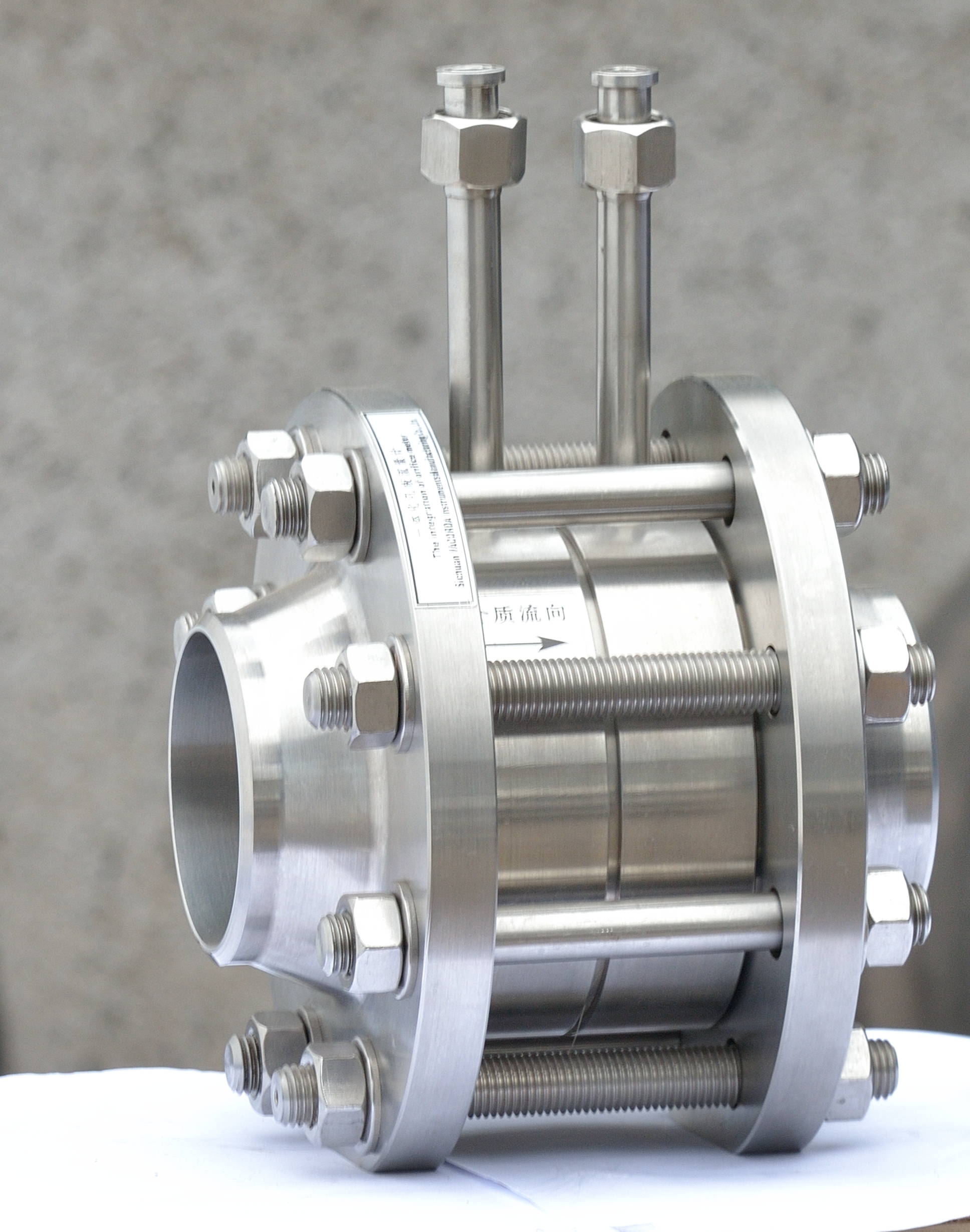

Post time: 21-09-21