The vortex flowmeter is suitable for a wide range of fluids, but it is not suitable for measuring low Reynolds number (ReD≤2×104) fluids. When the Reynolds number is low, the Strouhal number changes with the Reynolds number, the linearity of the meter becomes worse, and the fluid viscosity is high, which significantly affects or even hinders the generation of vortices. At the same time, there are requirements for the dirty properties of the fluid. The scouring of the vortex generator by the fluid containing solid particles will cause noise and wear to the vortex generator. If the short fibers contained are wound on the vortex generator, the meter coefficient will be changed. The applications of vortex flowmeters in mixed-phase fluids are as follows:① It can be used for gas and liquid two-phase flow with dispersed and uniform micro bubbles, but the volumetric gas content should be less than 7%-10%. If the volumetric gas content exceeds 2%, the meter coefficient should be corrected.②It can be used for gas-solid and liquid-solid two-phase flow containing dispersed and uniform solid particles with a content of not more than 2%.③It can be used for the two-component flow of insoluble liquid (such as oil and water).Pulsating flow and rotating flow will have a serious impact on the vortex flowmeter. If the pulsation frequency coincides with the vortex frequency, it may cause resonance, damage normal operation and equipment, and cause the vortex signal to “lock-in”. At this time, the signal is fixed at a certain frequency. “Lock-in” is related to the pulsation amplitude, the shape of the vortex generator and the blocking ratio.The accuracy of the vortex flowmeter is approximately ±(0.5%~±2%)R for liquids and ±(1%~±2%)R for gases, and the repeatability is generally 0.2%~0.5%. Because the meter coefficient of the vortex flowmeter is low, the frequency resolution is low, the larger the caliber, the lower the accuracy, so the meter caliber should not be too large (below DN300).The wide range is the advantage of the vortex flowmeter, and the flow value of the lower limit of the range is more important. Generally, the lower limit of the average flow velocity of liquid is 0.5m/S, and that of gas is 4~5m/s. The normal flow rate of the vortex flowmeter is at 1/2~2/3 of the normal measurement range.The advantage of the vortex flowmeter is that the meter coefficient is not affected by the physical properties of the measuring medium. It can be calibrated with a typical medium and applied to other mediums, which provides convenience for solving the problem of calibration equipment. However, due to the large difference in the flow rate range of liquid and gas, the frequency range is also very different. In an amplifier circuit that processes vortex signals, the passband of the filter is different, and the circuit parameters are also different. Therefore, the same circuit parameter cannot be used to measure different media. After the medium is changed, the circuit parameters should also change accordingly.In addition, the density of gas and liquid is very different, and the signal intensity generated when the vortex is separated is proportional to the density. Therefore, the signal strength is also very different, the gain and trigger sensitivity of the liquid and gas amplifier circuits are different, the piezoelectric charge is very different, and the parameters of the charge amplifier are also different. Even if the same gas (or liquid, steam, etc.), with the different medium pressure, temperature or density, the flow range used is different, the signal strength is also different, and the circuit parameters also need to change. Therefore, it is not feasible for a vortex flowmeter to change the medium or gauge diameter without hardware or software modification.

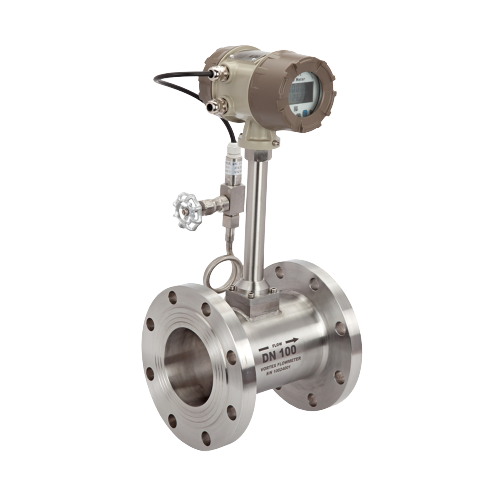

Vortex flowmeters are widely used in industrial sites such as water treatment and oil pipelines.

Post time: 21-09-21