In the liquid chemical production such as petroleum refining, the inletand outlet materials of the equipment are mainly steam, gas energy and liquidraw materials and products. These materials all require high-precisionmeasuring instruments. Therefore, the production workshop requires very strictrequirements for the metering of the materials in and out of the equipment. .

The failure of the mass flow meter in use is generally divided into twocategories: measurement failure caused by process reasons and failure caused bydamage of the flowmeter itself.

1. Measurement failure caused by process reasons:

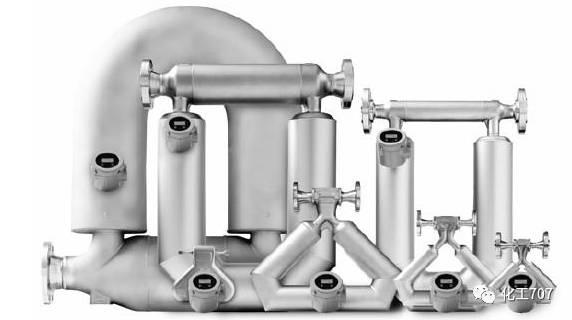

The most common is the phenomenon of two-phase flow in the fluid beingmeasured. Specifically, the measurement of the liquid is mainly that the liquidto be tested is not filled with the flow meter measuring tube or the uppercollecting gas of the measuring tube, or the solid impurities enter themeasuring tube, causing the mass flow meter to be faulty.

Treatment method: Ensure that the fluid measured by the mass flowmeter isa unidirectional flow by means of changing the installation mode of the exhaustgas, and take measures to remove solid impurities in the measuring tube.

2. The flowmeter itself is damaged due to damage to the mass flowmeter:

The most common use is the failure of the flowmeter junction box to enterthe water or loose wiring to cause short circuit and signal loss.

Treatment method: In addition to strict specification of on-siteinstallation, daily routine inspection and maintenance should be carried out toprevent more serious failures such as burning of sensor coils in time.

3. The transmitter board is damaged. The most common fault occurs when thetransmitter’s power board and signal processing output board are damaged.

Treatment method: In addition to strict specification of cable signalwiring, lightning protection grounding measures should be taken. Independentpower supply should be used to ensure the reliability of the power supply andprevent the power supply voltage from fluctuating greatly and burn the device.

Split-type mass flowmeter, because the signal cable connection pipe is notwell sealed, causing rainwater to leak into the sensor and burn the drive coil.

Sichuan VacordaInstruments Manufacturing Co., Ltd

21 Years FocusedonLevel MeasurementinExtremeProcessConditions

Tel: +0086 288701 3699

Email: sales@vacorda.com

Web: www.vacorda.com

Post time: 21-09-21