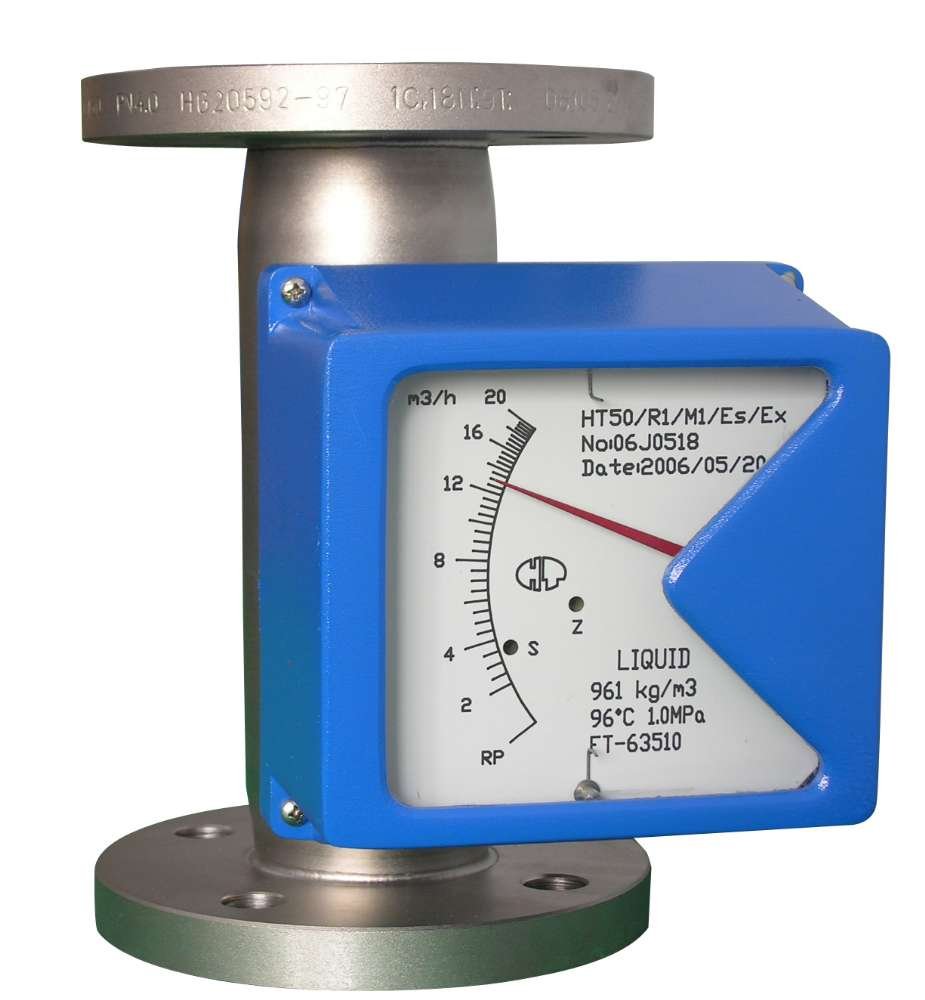

The metal tube float flowmeter is the most common type of flowmeter in industrial production. It is suitable for measuring the flow of small-diameter and low-velocity media within DN200; it is reliable in operation, small in maintenance, and long in life; it is not demanding for straight pipe sections; Wide flow ratio 10:1; double-line large liquid crystal display, optional on-site instantaneous/cumulative flow display, single-axis sensitive indication with backlight; non-contact magnetic coupling transmission; all-metal structure, metal tube rotor flowmeter suitable for high temperature , High pressure and strong corrosive medium; It has the characteristics of simple structure, reliable work, wide application range, accurate measurement and convenient installation. It can be used in flammable and explosive hazardous situations; optional two-wire system, battery, AC power supply; multi-parameter calibration function; with data recovery, data backup and power failure protection functions. About the troubleshooting method of metal flowmeter:1. The pointer of the metal tube float flowmeter stops moving at a certain position. The main reason is that the float of the metal tube float flowmeter is stuck.Generally, when the metal tube float flowmeter is in use, the valve is opened too fast, so that the float rushes upwards to the stopper, causing the stopper to deform and jam the float. However, it does not rule out that the float guide rod and the stop ring are not concentric, causing the float to jam. When handling, remove the meter, remove the deformed stopper and reshape it, and check whether it is concentric with the guide rod. If it is not concentric, you can correct it, then install the float, push the float by hand, and feel that the float is unobstructed up and down. Yes, in addition, the metal tube float flowmeter must be installed vertically or horizontally, and not inclined, otherwise it will easily cause the meter to jam and bring errors to the measurement.2. The pointer of the metal tube float flowmeter jitters:1. Slight pointer jitter: Generally caused by medium fluctuations. It can be overcome by increasing damping.2. Moderate pointer jitter: Generally caused by the flow of the medium. For gas, it is generally caused by unstable operating pressure of the medium. The pressure stabilization or flow stabilization device can be used to overcome or increase the gas damping of the metal tube float flowmeter.3. Severe pointer jitter: Mainly due to medium pulsation, instability of air pressure or the pressure, temperature, and flow rate of the gas operating state given by the user do not match the actual state of the metal tube float flowmeter. Large differences cause the metal tube float flowmeter to over-range.Three, no current output1. First check whether the wiring is correct.2. Whether the LCD has display, if there is no output, the output tube is mostly broken and the circuit board needs to be replaced.3. The calibration value is missing. Due to the E2PROM failure, the calibration data of the meter will be lost, and no output current will be caused, and the current will remain unchanged. Solution: Available data recovery operation.Four, no on-site display1. Check whether the wiring is correct. 2. Check whether the power supply is correct. 3. Reinstall the LCD module and check that the contact is not real. 4. For multi-wire power supply mode, check whether the terminal is connected to an ammeter or is short-circuited.5. The alarm is incorrect 1. Check that the deviation setting d value cannot be too large. 2. Whether the logic function is correct. HA-A represents the upper limit positive logic. LA-A means lower limit positive logic. 3. Check the alarm value setting size. 4. If the LCD bar code indication is correct and the output has no action, check whether the external power supply and the negative pole of the external power supply are connected to the negative pole of the power supply of the instrument. 5. The circuit board is faulty, replace the circuit board.Six, the on-site LCD always displays 0 or full scale 1. Check the set range and zero point parameters. ZERO is required to be less than the value of SPAN, and the two values cannot be equal. 2. Check whether the sampled data is up, and push the pointer with your hand to watch the sample value change. If there is no change, it is generally because the circuit board sampling circuit is faulty, and the circuit board needs to be replaced.Seven, the measurement error of the metal tube float flowmeter is large 1. Installation does not meet the requirements There must be no ferromagnetic objects. The installation location should be far away from the valve reducing port, pump outlet, process pipeline turning port, etc. The requirement of 250mm straight pipe section after the first 5D should be maintained.2. The large change in the density of the liquid medium is also a cause of the large error. Before the meter is calibrated, the medium is converted according to the density given by the user and converted to the flow of water in the calibrated state for calibration. Therefore, if the density of the medium changes greatly, it will cause a large error in the measurement. The solution can be to bring the changed medium density into the formula and convert it into an error correction coefficient, and then multiply the flow rate measured by the flowmeter by the coefficient and convert it to the real flow rate.3. Because the gas medium is greatly affected by temperature and pressure, it is recommended to use temperature and pressure compensation to obtain the true flow rate.4. Due to multiple factors such as long-term use and pipeline vibration, the moving parts of the metal tube float flowmeter, such as the sensing magnet, pointer, counterweight, and rotating magnet, become loose, causing large errors. Solution: You can verify by pushing the pointer first. First press the pointer at the RP position to see if the output is 4mA and the flow display is 0%, and then verify according to the scale in turn. If you find any discrepancies, you can adjust the position of the parts. Generally, professionals are required to adjust, otherwise it will cause the position to be lost and need to be returned to the manufacturer for calibration.

Post time: 21-09-21