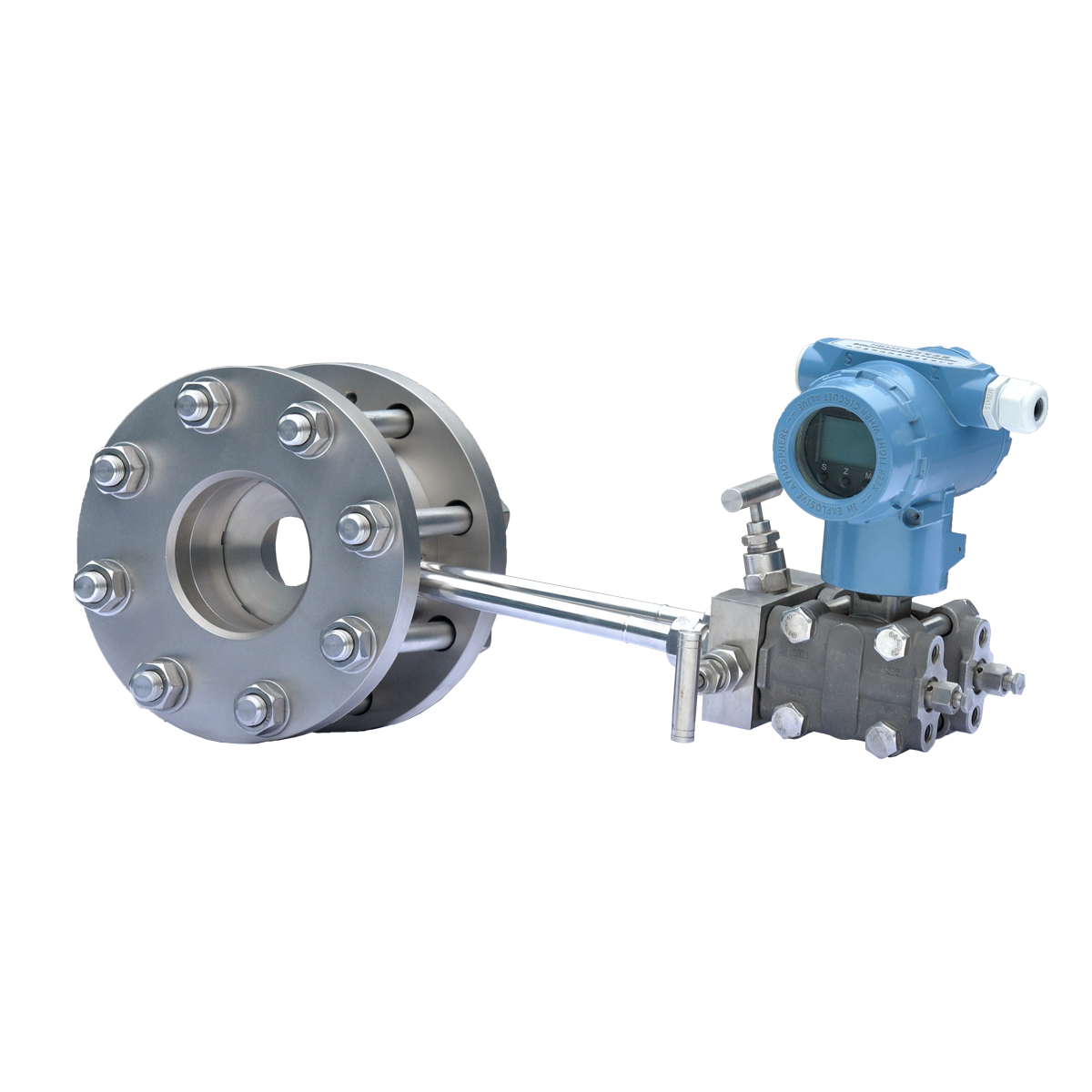

Orifice flowmeter is a throttling device and a differential pressure sensing element for measuring flow. It can be used to measure, integrate and control the instantaneous flow and cumulative flow of liquid, steam and gas in conjunction with a differential pressure transmitter and actual, recording, accumulating and regulating instruments.The throttling device has a simple structure, easy installation, reliable use, low price, convenient maintenance, and a wide range of options (standard section devices can measure pipe diameters from 50mm to 1200mm, and non-standard throttling devices can also be as small as 6mm. As large as 3000mm; the measurement temperature can be as high as 555℃; the pressure resistance can reach 42MPa), and the standard throttling device also has the advantages of not requiring separate calibration. It is the most widely used and most mature product in flow meters, so it is widely used Electricity, chemical industry, metallurgy, petroleum, textile, military and other fields.The throttling device is composed of a throttling piece, a pressure-taking device (including a pressure-taking port, a pressure pipe, a valve, etc.), a matching flange, and sometimes includes front and rear straight pipe sections that meet the standard. The standard throttling device includes a standard orifice plate, a standard nozzle, and a standard venturi tube. The standard orifice plate is divided into angle connection (ring chamber or drilling) pressure, flange pressure, and diameter pressure according to the pressure method; the standard nozzle is divided into nozzles and long diameter nozzles according to the form; the standard venturi is divided into venturi according to the form Nozzle, venturi tube (rough casting or machining or coiling). Non-standard throttling devices include small diameter orifice, 1/4 round orifice, round orifice, round orifice, eccentric orifice, double orifice, built-in orifice, tapered inlet orifice, etc. Other forms of throttling devices include pitot tube, velocities tube, wedge, cone and so on.When using a standard throttling device, the nature and state of the fluid must meet the following conditions: (1) The fluid must fill the pipe and the throttling device, and flow through the pipe continuously; (2) The fluid flow rate does not change with time or changes very slowly; ( 3) The fluid does not intersect when flowing through the throttle; (4) The fluid must be a Newtonian fluid, that is, physically and thermodynamically uniform, single-phase, or can be considered single-phase, including mixed gas, solution And colloids with dispersible particles less than 0.1m. There are no more than 2% (mass component) uniformly dispersed solid particles in the gas, or no more than 5% (volume component) uniformly dispersed bubbles in the liquid, which can also be considered as a single-phase fluid, but its density should be average. (5) Before the fluid flows through the throttle, the stream is a non-swirl flow parallel to the axis of the pipe.The standard throttling device is not suitable for flow measurement of dynamic flow and critical flow. The throttling device artificially causes throttling in the pipeline through which the medium circulates. When the measured medium flows through the throttling device, it causes a local contraction, the stream is concentrated, the flow velocity increases, and the static pressure decreases, so it is upstream and downstream of the throttling piece There is a static pressure difference on both sides. There is a certain functional relationship between the static pressure difference and the flow rate. The larger the flow rate, the greater the static pressure difference generated. Therefore, the flow rate can be measured by measuring the differential pressure.The difference between the orifice flowmeter and other flowmeters is that the orifice flowmeter is designed and manufactured according to the parameter design drawings and finally processed. It is only necessary to select the material of the orifice plate according to the measurement medium.

Post time: 21-09-21