In the electricalengineering, installation and construction, operation and maintenance andsafety technical management of explosion hazardous areas, explosion-proofmeasures must be taken to achieve overall explosion protection.

The explosion-proofinstrument does not have safety hazards, which can play a real protective role.Therefore, the safety inspection of explosion-proof electrical equipment ismainly aimed at the selection, installation and construction of explosion-proofelectrical equipment in explosion-hazardous places, whether it is standardizedand correct, whether there are defects in the facilities in use, and whetherthe management system is complete.

Factory explosion-proofinstruments have hidden dangers, is it safe?

1. The explosion-proof anddisturbing tube is not fixed and is not protected. If the instrument is removed,it should be blocked.

2. Why is the threadingpipe not blocked?

3. Cables in hazardouslocations should be protected by pipes!

4. The diameter of thecable is inconsistent with the size of the threading hole, and it is sealedwith explosion-proof glue.

5. The wiring hole isblocked, the insulation cotton can not be used!

6. The explosion-proof sealring is aging, it must be replaced in time!

7. The explosion-proofintroduction device is loose, what are you waiting for?

8.There is no effective isolation between different regional interfaces; theconduits or through holes on the wall of different explosion hazardous areasare not effectively blocked.

Accuratelyinstall and maintain factory explosion-proof instruments to make work safer!

Explosion-proofinstrument installation requirements

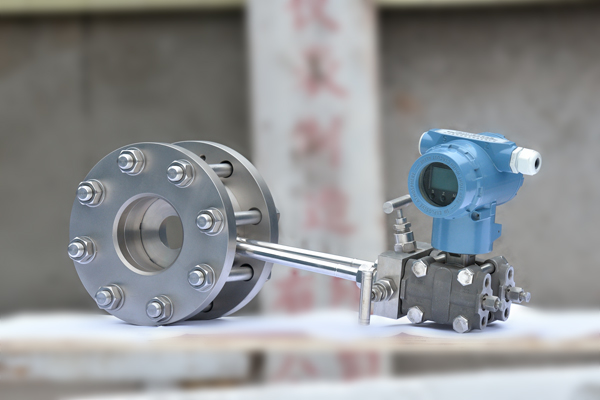

The instrument andinstallation materials installed in the explosion hazardous area shall havenameplate and explosion-proof mark. Before installation, check whether themodel and specification meet the design requirements, and there should be nodamage or crack on the outside.

For wiring of instrumentsin explosion hazardous areas, cables and wires must be laid with galvanizedsteel pipes. Between the thread-protecting tubes, the protective tube and thejunction box and the cable box should be connected by a cylindrical pipethread.

When protective tubes,sinks, and cable trenches pass through different levels of explosion hazardousarea boundaries, sealing measures (such as explosion-proof flame arresters,seal assembly isolation, filling and sealing, etc.) should be taken to preventexplosive gases from being struck from a hazardous location. Into anotherdangerous place.

When the protection tube isconnected with the field instrument, detection component, electrical equipment,instrument box, junction box and cable box, the explosion-proof sealing pipefitting should be installed within 0.45m of the joint, and if necessary, filland seal. A flexible pipe connection can be used between the sealed pipefitting and the field instrument, the detecting component, andthe electrical equipment.

2explosion-proof instrument filling and sealing

The filling seal is also called a glueseal or a glue seal, that is, a seal that is poured into the glue.

The explosion-proof cable gland shall befilled and sealed in the following cases:

Since the diameter of the cable and thediameter of the sealing joint are not matched, it is looser and smaller thanthe diameter of the sealing joint; when 2 to 3 cables are simultaneouslyconnected through a sealed joint.

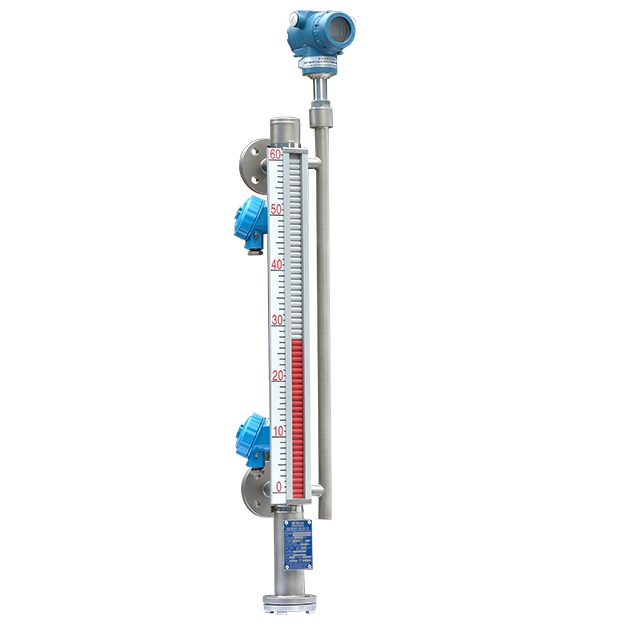

Inspection andmaintenance should be carried out frequently. The inspection should look at theappearance of the instrument, the environment (temperature, humidity, dust,corrosion), vibration, and whether the installation is firm.

When the explosion-proofinstrument is to be maintained under power-on conditions, the junction box andthe observation window must not be opened. The power must be cut off beforeopening the cover. Never open the cover for maintenance.

No sparks may begenerated during maintenance. The test instrument used shall be anexplosion-proof or intrinsically safe type of instrument to prevent the testinstrument from causing induced sparks or directing excessive voltage to aninappropriate location.

When disassembling, careshould be taken to protect the explosion-proof thread and the explosion-proofplane. It must not be damaged or scratched. In particular, longitudinalscratches are not allowed on the explosion-proof plane.

When disassembling therubber sealing element, do not use a sharp instrument to harden it, harden it,and do not have any longitudinal scratches on its sealing surface.

When assembling, itshould be carried out in the order of assembly, and the anti-loose parts andfasteners must not be leaked.

Corroded and damagedcomponents should be replaced in time, and the rubber sealing components thatare aging, damaged, and not sealed should be replaced in time.

After the instrument isregularly inspected, it must be confirmed that the explosion-proof performancehas been restored before it can be put back into use!

Sichuan VacordaInstruments Manufacturing Co., Ltd

21 Years FocusedonLevel MeasurementinExtremeProcessConditions

Tel: +0086 28 8701 3699

Email: sales@vacorda.com

Web: www.vacorda.com

Post time: 21-09-21