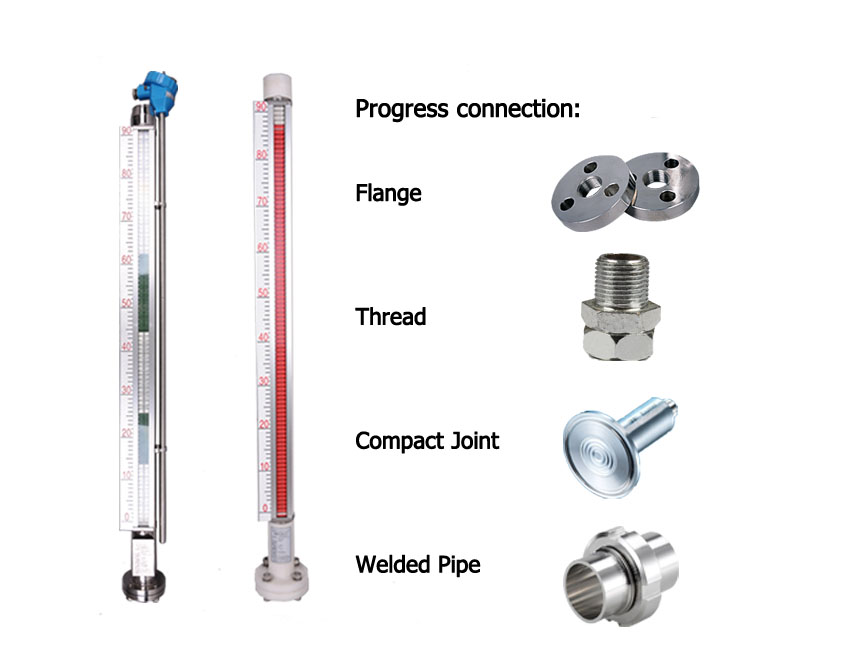

In order to find the best level meter when buying a magnetic plate level meter, several methods must be used to select it. Now, let’s take a look at the selection method of the magnetic flap level gauge with Huikeda Instruments. What is the working principle of the magnetic level gauge?Disk water level gauge selectionHow to choose disk water gaugeFirst, judging from the appearance of the magnetic flap, there are side-mounted and top-mounted types. Generally, the side-mounted type is used evenly for the general magnetic flap level gauge, and the top-mounted type is required under special circumstances.Second, the flange size generally refers to the size of the installation port with the tank, usually DN25, DN50, DN80 and other common installation dimensions, and can also be selected according to the connection mode of the tank.Third, the option with heat requires the use of heat-accompanying options for certain special media, such as cooling, heat, corrosion and other media, usually in the form of structures without heat, steam jackets, heat with electricity, and vacuum jackets.Fourth, the indicator type refers to several general displays that can clearly see the display data of the panel, such as magnetic flip display, magnetic flip vacuum panel display, magnetic flip column display, smart LED magnetic panel display, LED magnetic panel display, etc.Fifth, the second-line remote signal output with remote transmission function, 4-20mA clarinet transmitter, 4-20mA clarinet transmitter (with display), 4-20mA HART clarinet transmitter), 4-20mA HART Magnetostrictive transmitter), no transmitter. Disk water level gauge selectionWhat is the structure of the magnetic reflector level gaugeThe anti-plate level gauge application level gauge is developed based on the principle of buoyancy and magnetic coupling. When the liquid level in the container to be measured rises, the float in the main pipe of the level gauge also rises, and the permanent magnet steel in the float is transferred to the field indicator through magnetic coupling, so that the red and white reversal columns are reversed by 180 degrees, and the liquid level The reversal column changes from white to red when the level rises, and the reversal column changes from red to red when the liquid level drops. The measurement is reliable and safe, which makes up for the lack of unclear and fragile indications of the glass plate level gauge, and is not affected by the drastic changes in high and low temperatures. The whole process of multi-group liquid level measurement has no dead corners, eye-catching, intuitive readings and measurement wide range. It has higher reliability, safety, advancement and practicality.Magnetic plate level gauge is the most commonly used level gauge. The editor introduced the selection method of the magnetic flap level gauge above, I hope it will be helpful to everyone.

Disk water level gauge selectionWhat is the structure of the magnetic reflector level gaugeThe anti-plate level gauge application level gauge is developed based on the principle of buoyancy and magnetic coupling. When the liquid level in the container to be measured rises, the float in the main pipe of the level gauge also rises, and the permanent magnet steel in the float is transferred to the field indicator through magnetic coupling, so that the red and white reversal columns are reversed by 180 degrees, and the liquid level The reversal column changes from white to red when the level rises, and the reversal column changes from red to red when the liquid level drops. The measurement is reliable and safe, which makes up for the lack of unclear and fragile indications of the glass plate level gauge, and is not affected by the drastic changes in high and low temperatures. The whole process of multi-group liquid level measurement has no dead corners, eye-catching, intuitive readings and measurement wide range. It has higher reliability, safety, advancement and practicality.Magnetic plate level gauge is the most commonly used level gauge. The editor introduced the selection method of the magnetic flap level gauge above, I hope it will be helpful to everyone.

Post time: 21-09-21