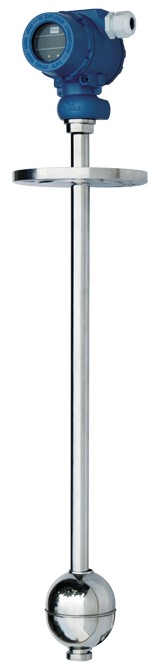

The float level gauge is designed according to the Archimedes buoyancy principle, and it is widely used in petroleum, chemical, food, environmental protection and other industries. But it is such a very common liquid level measuring instrument, if it is not selected properly, it will not be able to achieve liquid level measurement well. So, how to choose a float level gauge? Generally speaking, when selecting a float level gauge to measure the liquid level, the following parameters and factors need to be considered for selection:First, determine the material of the selected float level gauge according to whether the measuring medium is corrosive.If it is only a general corrosive liquid, 316L can be used. The corrosiveness exceeds the corrosion resistance of 316L. The probe, float and process connection materials of the float level gauge should also be made of plastic/PP or lining. Fluorine treatment;Secondly, the range and the length of the connecting rod are different and need to be clarified.Since the floating ball on the connecting rod needs to be limited when moving up and down, the actual rod length exceeds the range. After confirming the range, it is also necessary to communicate with the manufacturer how long the actual length of the connecting rod is to avoid failure to install on site;Thirdly, if the measured medium contains many impurities, it should be selected carefully.

Since the float level gauge works according to Archimedes’ principle, the float ball of the float level gauge moves up and down with the change of the liquid level in the container, realizing remote detection and control of the page. However, if the measured medium is turbid and contains more impurities, the floating ball is easy to get stuck during the up and down movement, which will affect the liquid level measurement. Therefore, if there are many impurities in the medium, it should be carefully selected. In principle, it is not recommended to use a float level gauge for measurement. Finally, in addition to the above parameters, it is also necessary to pay attention to whether additional switch alarm point positions are required while continuous output; the accuracy of the measurement, whether the meter needs to be displayed, and the requirements of related explosion-proof parameters also need to be determined.

Post time: 21-09-21