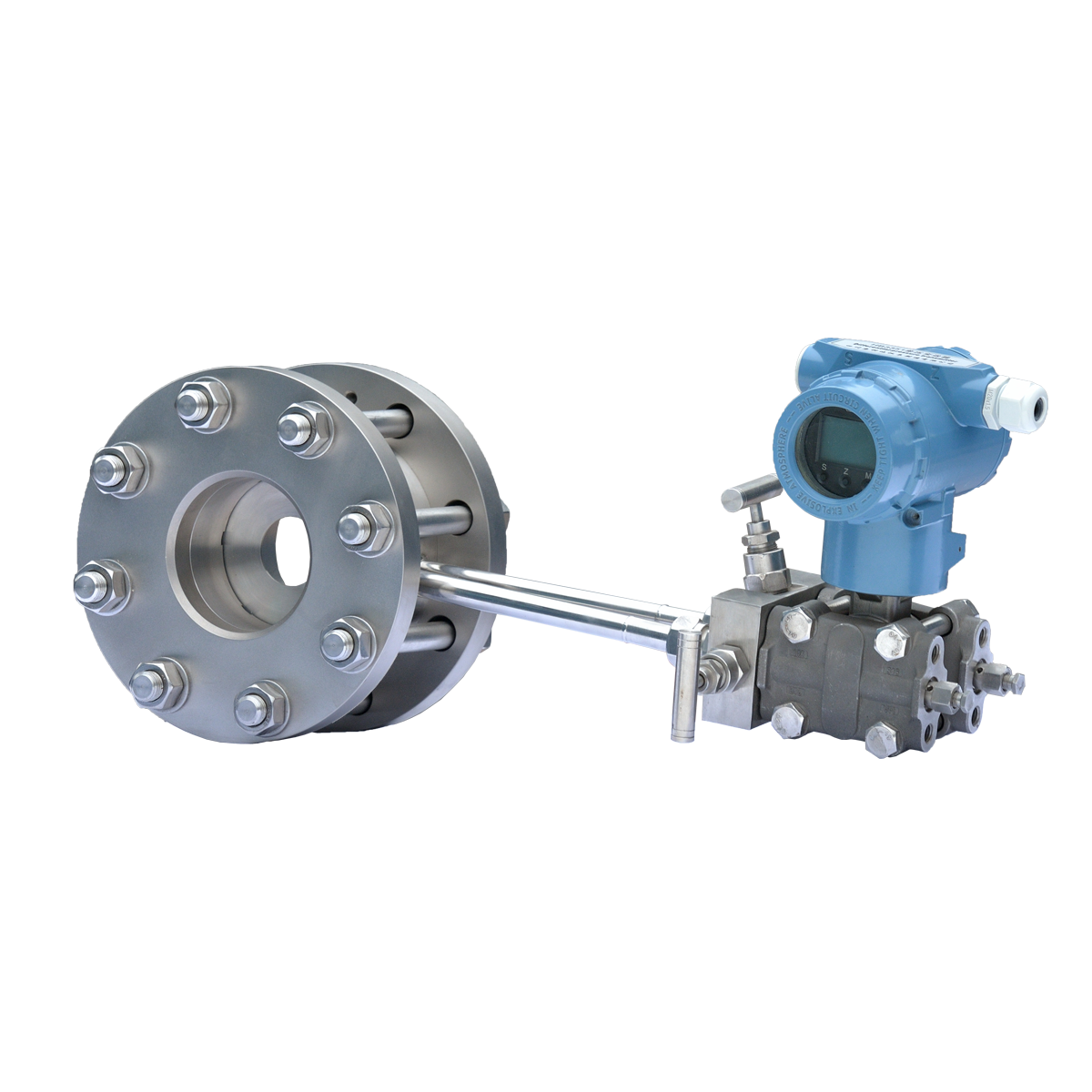

Orifice flowmeter is a differential pressure generating device that uses an orifice to match various differential pressure gauges or differential pressure transmitters to measure flow. It can measure the flow of liquid, steam, and gas. If you want to ensure that the orifice flowmeter can be normal After a period of time, the orifice flowmeter must be isolated and purged. The isolation of the orifice flowmeter uses an isolating liquid, and the diaphragm-type measured medium does not directly contact the flowmeter components, which can protect the orifice flowmeter and realize the measurement. For the measured liquid and corrosive gas with high viscosity, corrosiveness, and easy to release solids, an isolator must be used, so that the measured fluid will not directly contact the differential pressure gauge or differential pressure transmitter, so as to avoid The differential pressure transmitter or the differential pressure device is damaged. Purge is the use of air blowing or flushing to prevent the measured medium from directly contacting the flowmeter components and the measurement relationship. It is a method to protect the measuring instrument and implement the measurement. Blowing is the continuous and quantitative blowing into the gas through the measuring pipeline, and the flushing is the continuous and quantitative blowing into the liquid into the measuring object through the measuring pipeline. The purpose between the two is to prevent the measured medium from directly contacting the instrument components, so as to protect the orifice flowmeter and achieve the purpose of measurement.When the orifice flowmeter measures gas and steam, its medium must be cooled before it can come into contact with the secondary instrument and pressure transmitter. When the high temperature of the steam is responsible, the transmitter will not work or even be damaged. The transmitter is the main board. In order to avoid the influence of high-temperature medium on the differential pressure gauge, when measuring steam and water whose temperature is greater than 70°C, a condenser must be installed in the pressure guiding pipeline. The function of the condenser is to condense the measured steam in the pressure guiding tube, and make the condensate level in the positive and negative pressure pipes have the same height and remain constant. For corrosive media, the material of the measuring orifice flowmeter cannot meet the requirements of corrosion resistance. In order to protect the flowmeter, isolation can be used. For relatively viscous media, media containing solids, toxic media or at ambient temperature The media may be vaporized, condensed, crystallized, and precipitated. In order to achieve accurate measurement, isolation can also be used. The scope of purging application is limited to measuring the level, pressure, and flow of corrosive, viscous, crystalline, and precipitation media, and it is difficult to meet the requirements by using isolation methods. The vacuum object is not It is suitable to use the purge method for measurement.The orifice flowmeter is a differential pressure generating device for measuring the flowmeter. It is equipped with various differential pressure meters or differential pressure transmitters to measure the flow of various fluids in the pipeline. The accuracy of the measurement is closely related to the value of the differential pressure. . When selecting the differential pressure value, it is generally necessary to select the differential pressure value corresponding to the maximum flow rate. When the differential pressure value of the orifice flowmeter becomes larger, what is needed is that the smallest straight pipe section is shorter. For differential pressure transmitters, the larger differential pressure is more stable than the smaller differential pressure. When the differential pressure value becomes larger, the β value becomes smaller, so it is recommended to use the smallest Reynolds number, which will make the actual Reynolds number The number may be greater than the recommended Reynolds number, and when the flow coefficient is stable, the measurement accuracy will be improved. These factors may affect the repeatability of the orifice flowmeter. The repeatability is determined by the principle of the flowmeter itself and the manufacturing quality. It is an important indicator in the entire process control. In addition to the repeatability, the accuracy is also related to the value calibration system. In actual use, the excellent repeatability of the orifice flowmeter is affected by many factors, such as changes in fluid viscosity and density. The interference will lead to the accuracy of the measurement. If the output characteristic of the flowmeter is non-linear, this effect is more prominent.

Post time: 21-09-21