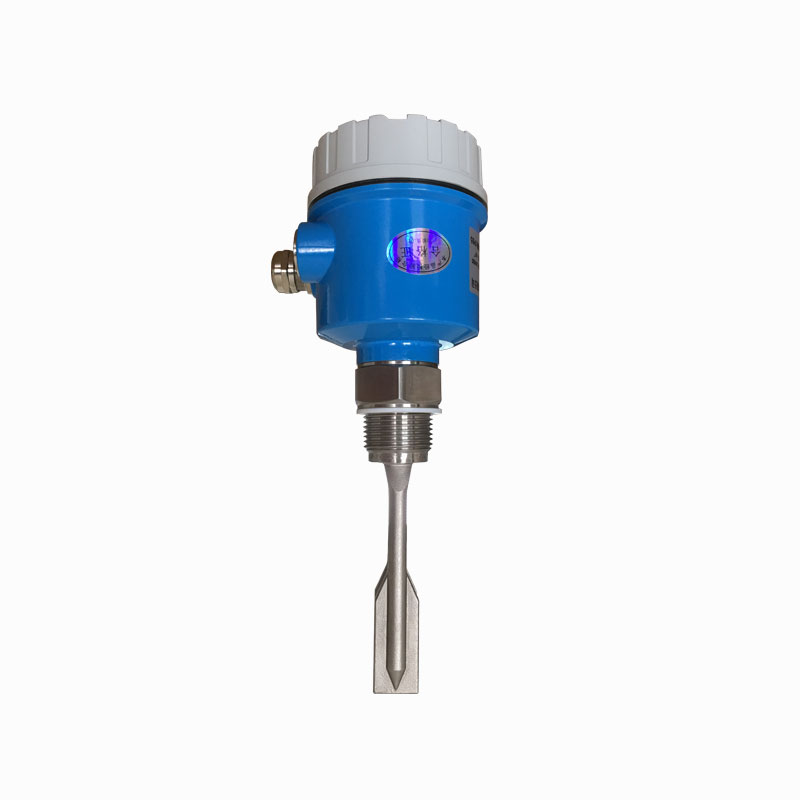

In many liquid level measurement applications such as chemicals and pharmaceuticals, the vibration of the storage tank caused by the flow, addition or discharge of liquid materials, and environmental factors will inevitably cause liquid level fluctuations, which will affect the accuracy of liquid level measurement Even lead to false alarms of the level switch. How to improve the reliability of product measurement and avoid the influence of waves on the reliable measurement of liquid level switches has put forward new requirements for liquid level switch manufacturers.First of all, choosing a high-quality liquid level switch can also effectively avoid the influence of waves on the liquid level and improve the reliability of the liquid level switch measurement. The R&D engineers of Sichuan Huikeda Instrument Manufacturing Co., Ltd. fully considered this influencing factor during the R&D process of the liquid level switch, and adopted a reasonable delay time when designing the circuit. These designs can effectively avoid the false alarm of the liquid level switch. And improve the accuracy of measurement. Strong anti-interference ability, free from the influence of foam, bubbles, viscosity, vibration and liquid characteristics; small allowable medium density as low as 0.5g/cm3, high temperature resistant design, process temperature up to 250℃, industry-leading; based on testing The design of frequency change has high reliability.Secondly, choosing the best installation location and correct installation method can also appropriately avoid the influence of waves on liquid level measurement and improve the reliability of liquid level switch measurement. When installing the liquid level switch, the choice of position and insertion length is also very important. According to the actual application of the site, try to choose a place with slight waves for liquid level measurement, and try to stay away from the inlet (feeding) inlet and outlet; For applications with stirring, the installation position of the level switch should be as far away as possible from the stirring area. At the same time, the appropriate installation height and insertion length can be selected according to the height of the liquid level alarm. In applications with waves, the same installation height, different insertion lengths, and the alarm height are obviously different. At the same time, the difference in the installation angle will affect the alarm. The height of the liquid level will also be different.

Post time: 21-09-21