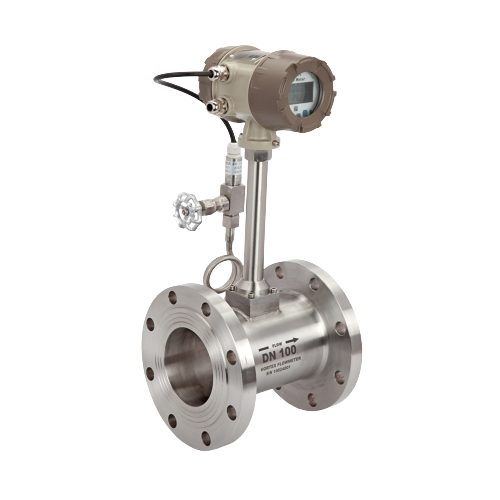

Intelligent vortex flowmeters are mainly used for flow measurement of industrial pipeline fluids, such as gases, liquids, vapors and other media. It is characterized by small pressure loss, large range planning, and high accuracy. It is hardly affected by fluid density, pressure, temperature, viscosity and other parameters when measuring volume flow under working conditions. There are no movable mechanical parts, so the reliability is high and the maintenance is small. The surface parameters can be stable for a long time. The surface adopts piezoelectric stress sensor, which has high reliability and can work within the working temperature plan of -20℃~+250℃. There are analog standard signals and digital pulse signal outputs, which are easy to be used in conjunction with digital systems such as computers. It is a flow surface that compares ling and aspirations.Common problems encountered in the use of intelligent vortex flowmeters are as follows:Mainly include: ①The indication is inaccurate for a long time; ②There is no indication at all; ③The indication plan is not firm and cannot be read; ④The indication does not return to zero; ⑤There is no indication when the flow rate is small; Inaccurate; ⑦ can not keep up with the indication change when the flow is changed; ⑧ surface K coefficient cannot be determined, and many data are different.The solution involves the following aspects:1. Questions about model selection. For some vortex sensors, the diameter selection may be due to changes in technical conditions after the planned selection, which makes the selection larger-a specification. The practice selection should be as small as possible to improve the measurement accuracy. The main reason for this is It is related to questions ①, ③, and ⑥. For example, a vortex pipeline is planned for several equipment applications, and some equipment is sometimes not used due to the skills, and the current flow rate of the practice application is reduced. The original plan selection of the practice application composition is too large, which is equivalent to the advancement of the measurable flow rate. The lower limit, the instruction cannot be guaranteed when the flow of the skill pipeline is small, and it can be used when the flow is large, because it is sometimes too difficult to rebuild from scratch because of the assumption. The change in skill conditions is only temporary. Re-tuning of parameters can be contacted to advance indication accuracy.2. Questions about equipment. Mainly because the length of the straight pipe in front of the sensor is irrelevant, which affects the measurement accuracy, the reason for this is mainly related to question ①. For example, the straight pipe section in front of the sensor is significantly short. Since FIC203 is not used for measurement, but only for control, the current accuracy can be used as degraded application.3. The reason for the parameter setting direction. Due to parameter error, the surface indication is wrong. The parameter error makes the calculation error of the secondary surface full-scale frequency. The reason for this is mainly related to the questions ① and ③. The same full-scale frequency makes the indication inaccurate for a long time, and the full-scale frequency of the practice full-scale calculation makes the indication plan unstable and unable to read, and the divergence of the parameters in the data affects the final judgment of the parameters. After all, the parameters were determined by comparison with each other through the re-calibration contact, and this question was dealt with.4. Disadvantages of secondary surface. This has some disadvantages, including: once the surface circuit board is disconnected, the range setting has a single bit flashing broken, and the K coefficient setting has a single bit flashing broken, making it impossible to determine the range setting and the K coefficient setting. Some reasons are mainly related to questions ① and ②. By correcting the corresponding shortcomings, the doubts are dealt with.5. Questions about the four-way line connection. On the surface of some circuits, the circuit connection is very good. Check carefully. Some joints have been loosened to form a circuit break. Some joints are tightly connected, but the fastening screws are fastened to the wire skin due to the doubt of the secondary line, which also makes the circuit. Intermittent, some of these reasons are mainly related to question ②. dealt with the corresponding line questions, and the existing questions were dealt with accordingly.6. Questions about the connection between the secondary surface and the subsequent surface. Due to the question of the follow-up surface or the repair of the follow-up surface, the mA output loop of the secondary surface is interrupted. For this type of secondary surface, some of the reasons are mainly related to the question ②. Especially for the follow-up recorder, if the recorder is damaged for a long time and cannot be corrected, you must be careful to short-circuit the output of the secondary surface.7. Due to the shortcomings of the secondary surface flat-axis cable, there is no indication for the loop. Due to long hours of work, coupled with the impact of dust, it constitutes the shortcomings of the flat shaft cable. The problem can be resolved by cleaning or replacing the flat shaft cable.8. For the question ⑦, the main reason is that the secondary surface flashes that the fixing screw of the meter head coil is loose, which constitutes the meter head sinking, the pointer and the watch case are in large conflict, and the movement is not working properly. By adjusting the meter head and fixing it from the beginning, the question should be dealt with accordingly.9. Use environmental questions. Especially some sensors in the equipment in the ground well, due to the high humidity in the environment, the circuit board is damp. Some of these reasons are mainly related to questions ② and ②. Through corresponding technical improvement methods, some sensors with high environmental humidity have been re-processed separately from the replacement of some probes and changed to separate sensors, so the working environment has been improved, and some of these surfaces have worked well recently.10. Due to poor on-site adjustment, perhaps due to further changes in the internship situation in the future. Due to on-site vibration and noise balance adjustment and sensitivity adjustment is not good. Perhaps due to adjustments and subsequent work for a period of time, the on-site situation will change again, which constitutes an instruction question. Some of these reasons are mainly related to questions ④ and ⑤. Use an oscilloscope, plus contact skills and work conditions to adjust from scratch.

Post time: 21-09-21