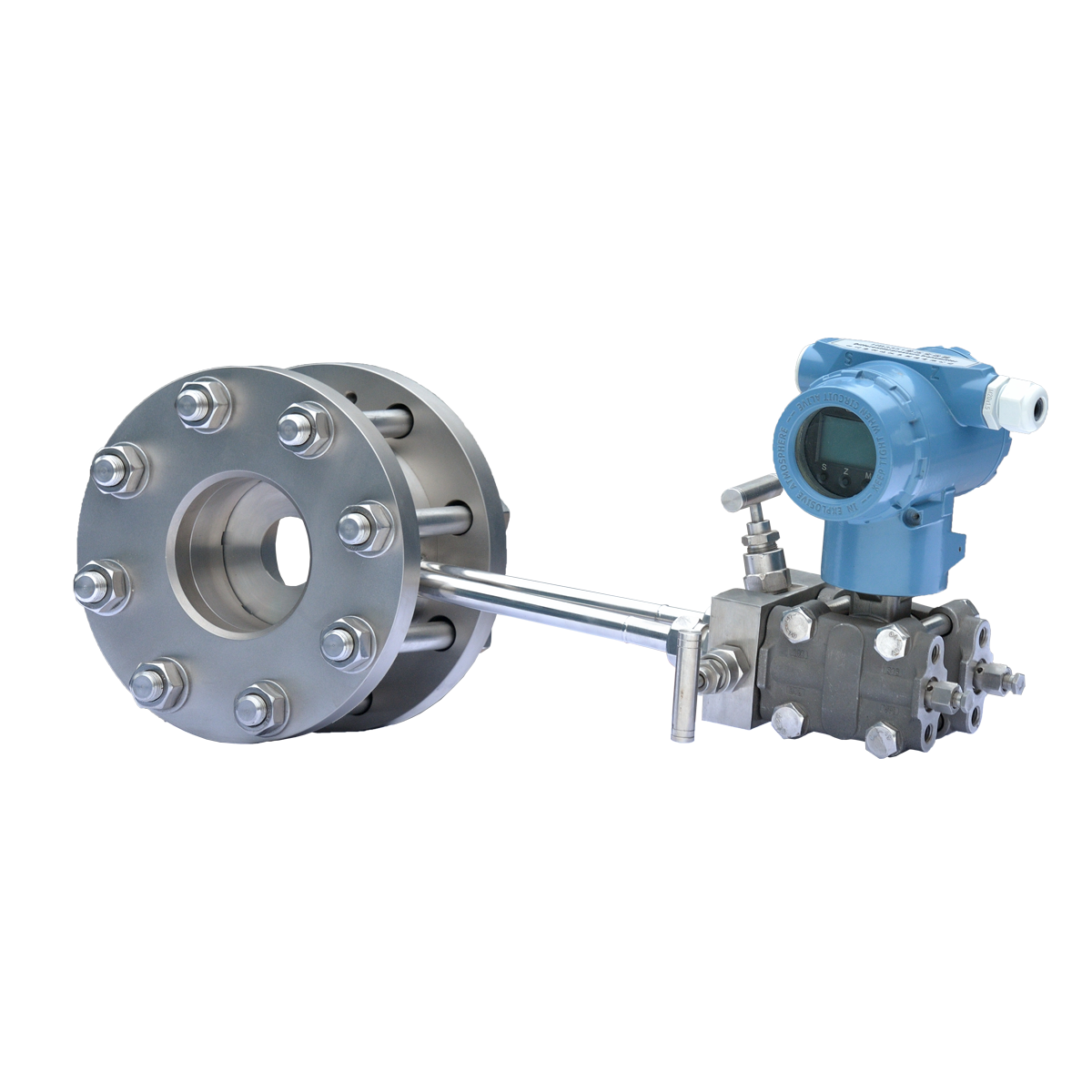

Measures to improve the accuracy of standard orifice flowmeters In order to improve the accuracy of standard orifice flowmeters, the following measures can be taken:1. Manufacture and installation of standard orifice plate throttling deviceThe use of standard orifice flowmeters to measure natural gas flow must strictly follow the technical indicators specified in the SY/T6143-2004 standard, and the standard orifice throttling device must be designed, manufactured, inspected, installed and used. Especially the processing and inspection of the sharpness of the right-angle entrance edge of the orifice plate and the roughness of the inner wall of the measuring tube; the guarantee of the length of the straight pipe section before and after the orifice plate, the roundness of the straight pipe section, the step and the coaxiality of the orifice plate and the measuring tube. In addition, the development of a unified standard orifice flowmeter design software can improve the technical level of throttling device design and instrument selection.2. Use replaceable orifice device and fixed value throttling deviceThe replaceable orifice throttling device is a new type of throttling device. The throttling element is installed in a fixed seat (the seat is connected to the pipeline by a flange), and the pipeline is not removed or the fluid transportation is not stopped. The orifice plate can be easily lifted for inspection, cleaning or replacement, thus ensuring the accuracy of measurement. Using hydraulic lifting device, the orifice plate is light and easy to lift, especially suitable for large-diameter orifice plates. This throttling device is also equipped with a cleaning chamber and a cleaning mechanism, which provides an effective means for solving the fouling medium, especially the accurate metering of single-well natural gas.The fixed-value throttling device changes the method of processing the aperture of the existing throttling device according to the calculation result. A limited number of throttling parts are provided for each diameter measuring pipe. The aperture series is selected according to the priority number system, and each diameter is equipped. 3 to 5 kinds of orifice plates with different aperture ratio β values. At present, the design of throttling device is like tailor-made clothing, and the fixed value throttling device becomes the choice of ready-made clothing. The use of fixed value throttling device is conducive to mass production of products, reduces production costs, facilitates selection and use, and facilitates supervision of production. The replacement of the orifice plate throttling device and the fixed value orifice plate will change the traditional production method, realize the serialization, generalization and standardization of the throttling device product, which is beneficial to improve the measurement accuracy of the standard orifice plate device.The disadvantage of the standard orifice is that the sharpness of the right angle of the entrance is prone to passivation under fluid washing. It is estimated that severe passivation may cause the outflow coefficient to shift by 1% to 2%, and the outflow coefficient is relatively stable after passivation, which brings great difficulties to the correction of the right angle sharpness of the orifice inlet in the flow calculation. The outflow coefficient of the standard nozzle is stable. In addition, the pressure loss of the nozzle is only 30% of the orifice plate at the same flow rate and the same β value. The main reason that affects the popularization of standard nozzles is the high cost of nozzle manufacturing. In the standard, the uncertainty of the outflow coefficient of the nozzle is relatively large (about 2%). The use of fixed-value throttling parts, special processing equipment to achieve mass production, reduce production costs, and individual calibration can obtain a high degree of outflow coefficient, the use of nozzles instead of orifices in natural gas flow measurement, the advantages are obvious.3. Apply a reasonable flow accumulation planAccording to the natural gas metering conditions and the user’s requirements for metering accuracy, an integration scheme of automatic partial compensation or full compensation for changes in pressure, temperature and natural gas composition to flow should be adopted. /T18603-2001 “Technical Requirements for Natural Gas Metering System”. Use intelligent differential pressure transmitter, pressure transmitter, temperature transmitter and flow computer to form an online detection system to compensate temperature and pressure changes, which can improve measurement accuracy and reduce flow caused by flow pulsation (or fluctuation) Measure additional error. The range ratio of orifice flowmeters is generally 1:3, and the actual measurement of natural gas flow changes sometimes exceeds this range. In this case, its measurement accuracy is significantly reduced. If a fixed-value throttling device is used, a wide-range intelligent differential pressure transmitter and a flow computer are used together, which can easily expand the flow range or migration range, and then realize the traditional standard hole The intelligence of the plate flowmeter.4. Establishing and improving various rules and regulations Strengthening measurement management, establishing and improving various rules and systems, and strictly implementing measurement regulations are the keys to ensuring the accuracy of orifice flowmeter measurement of natural gas flow. According to the GB/T18603-2001 “Technical Requirements for Natural Gas Metering System” standard, the unified orifice flowmeter measurement system is equipped with secondary measuring instruments according to the measurement systems specified by different scales. From the beginning of design, after construction, acceptance, commissioning, operation and maintenance, etc. All are implemented in accordance with unified technical requirements, so that the natural gas flow measurement, flow accumulation method, and flow calculation program software are all under strict technical requirements control, and comprehensive quality management can ensure the accuracy of flow measurement. In strict accordance with the SY/T6143-2004 standard, the “Standard Procedure for the Inspection of Flow Calculation Values” is compiled to strictly inspect the flow values calculated by various flow integration methods. The flow measurement uncertainty of the standard orifice flowmeter measurement system is evaluated, and the total flow measurement uncertainty of the measurement system should be lower than the maximum allowable error. Improve the measurement management system, and formulate an orifice flowmeter operation, use and management regulation that is matched with the SY/T6143-2004 standard and meets actual needs. Its contents include the establishment and improvement of the measurement management responsibility system at all levels, the periodic inspection and maintenance system of standard measuring instruments, the inspection, adjustment and maintenance system of working instruments, the data file management system of measuring equipment and measuring instruments, etc. While conscientiously implementing the SY/T6143-2004 standard and its related measurement standards, various measurement management regulations and management systems should be matched with them, strengthen the training of measurement technicians, and improve the technical management level of measurement personnel. [The content of this article (text) was compiled from the Internet, and the copyright belongs to the original author. If there is any infringement, please inform and we will delete it immediately.

[The content of this article (text) was compiled from the Internet, and the copyright belongs to the original author. If there is any infringement, please inform and we will delete it immediately.

Post time: 21-09-21