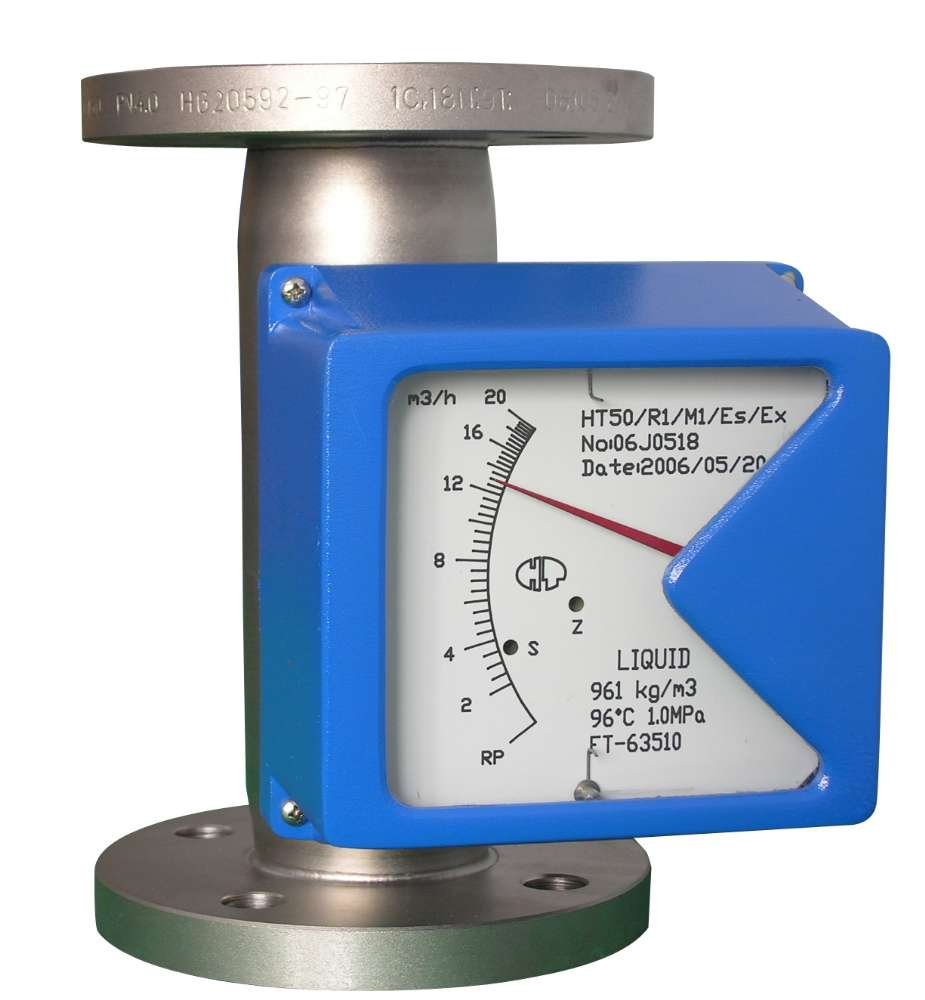

The metal tube float flowmeter adopts the variable area measurement principle for production research, and is suitable for measuring liquids and gases. All-metal structure, there are indicator type, electric remote transmission type, corrosion-resistant type, high voltage type, jacket type, explosion-proof type. With 0-10mA, 4-20mA standard analog signal output and on-site instructions. Accumulation, digital communication, field modification of measurement parameters, different power supply functions, with magnetic filters and special specifications.Precautions for use:1. Before installing the metal tube float flowmeter, be sure to clean up the welding slag and debris in the pipeline.2. In order to ensure the measurement accuracy of the metal tube float flowmeter, a straight pipe section of no less than 10DN should be added to the inlet end of the flowmeter, and a straight pipe section of no less than 5DN at the outlet end. The regulating control valve must be installed on the flowmeter during measurement. Downstream.3. If the measured medium is a large pulsating flow or two-phase flow, a buffer should be installed upstream of the metal tube float flowmeter to eliminate or reduce the pulsation and ensure that the flow of the medium is single-phase stable. At the same time, it is recommended that the flowmeter is the most Easy to use damping type.4. If the measured medium is dirty or contains magnetic particles, a filter or magnetic filter should be installed upstream of the metal tube float flowmeter.5. The installation of the metal tube float flowmeter should be able to properly support the vibration of the pipeline or reduce the axial load of the flowmeter, otherwise the support of the fixed flowmeter should be increased.6. In order to facilitate the maintenance of the metal tube float flowmeter, the cleaning of the magnetic filter and the regular maintenance of the user’s pipeline.7. When the metal tube float flowmeter is used for gas measurement, it should be ensured that the working pressure in the pipeline is not less than 5 times the pressure loss of the flowmeter, so that the flowmeter can operate stably and normally.8. Before using the electric remote transmission and the metal tube float flowmeter with alarm limit switch, open the meter cover, and wire it correctly according to the wiring diagram. For the alarm type of the screw at the limit switch, the user can set the limit alarm position as needed, tighten the screw, and use it after restoration.9. According to the warning sign in the indicator of the meter, take out the stopper that prevents the float from vibrating during transportation, and use the meter after restoration.10. If the metal tube float flowmeter is turned on, because there is no pressure in the pipeline or the system has not yet reached the working pressure of the instrument, the control valve must be slowly opened until the system is normal before the instrument can be used, otherwise it will easily cause the pointer to jump or float. The phenomenon of damage caused by sudden impact.11. When the user uses, if the density of the measured fluid is different from that of water, or the parameters and working conditions of the measured gas are different from those specified by the manufacturer, the metal tube float flowmeter should be converted.

Post time: 21-09-21