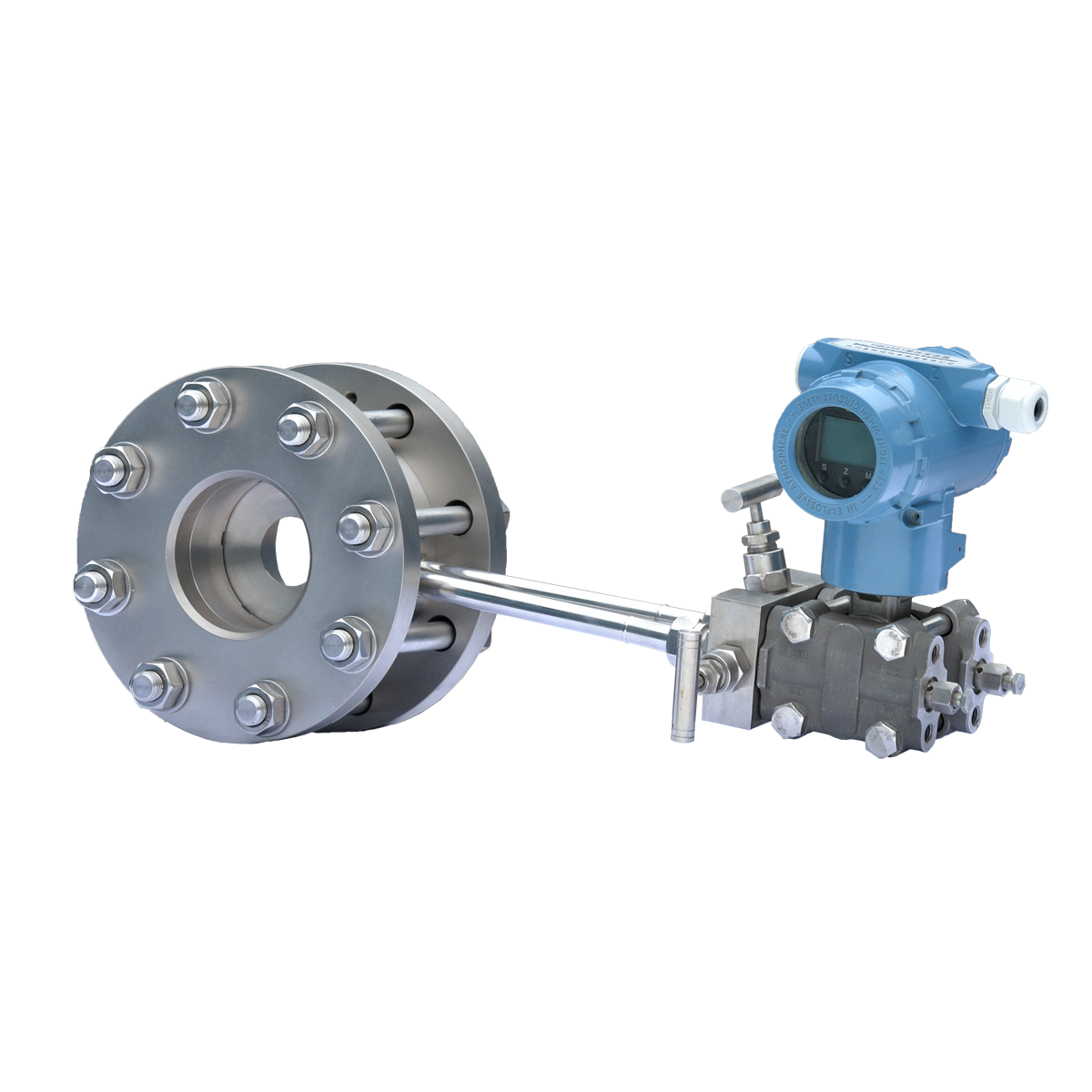

The integrated orifice flowmeter consists of three parts: sensing, transmission, and calculation display. It is mainly suitable for industrial measurement of saturated steam, superheated steam, compressed air, mixed non-flammable and explosive gas and hot water. It can be used for flow measurement, display, metering and online automatic control of production process.1. It must be filled with water or injected high-temperature steam in the pressure guiding tube to cool down before starting the operation. The straight pipe sections before and after the throttling part of the integrated orifice flowmeter must be straight. The straight pipe section used to install the throttling part should be smooth. If it is not smooth, the flow coefficient should be multiplied by the roughness to correct the sparseness.2. A sufficiently long straight pipe section is required before and after the throttle. When the upstream side of the throttle is an open space or a large vessel with a diameter of ≥2, the open space or the straight pipe length between the large vessel and the throttle shall not be less than 30 ( 15). If there are other local resistance parts between the throttling part and the open space or large container, in addition to the minimum straight pipe length 1 between the throttling part and the local resistance part, from the open space to The total length of the straight pipe section between the throttles shall not be less than 30 (15).How to use the integrated orifice flowmeter correctly:1. The pressure guiding pipe system is filled with cold water as the pressure guiding medium, and the measurement of high temperature steam is generally conducted through the cold water. When there is no steam in the pipeline, open the primary valve, pressure valve and balance valve, close the drain valve, and directly inject cold water from the water injection hole of the condensate tank until it is fully filled. Of course, you can also close the balance valve and pressure valve, and open the primary valve to introduce high-temperature steam and slowly cool it into water. This method is generally not used because the steam temperature is too high and it is easy to damage the instrument. Special attention should be paid to when the pressure guiding tube is not filled with water or the temperature is high when measuring high temperature steam, it is strictly forbidden to put it into operation.Precautions for the use of integrated orifice flowmeter:1. Measure compressed air and cold water directly by using the medium to conduct pressure. 2. After the differential pressure transmitter is exhausted or drained, after the pressure guiding tube is filled with water, a small amount of gas may accumulate in the pressure chamber of the differential pressure transmitter to affect the guiding pressure, which must be eliminated. 3. Unscrew the bolts at the bottom of the positive and negative pressure chambers to drain the liquid. Generally, the newly put into operation meter does not need to drain liquid. Check that there is no leakage in the pressure-conducting pipeline system, close all valves, and prepare to be put into operation.

Post time: 21-09-21