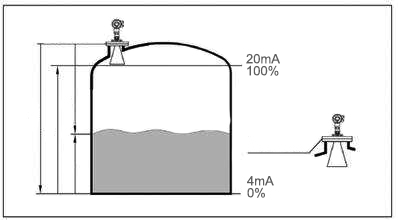

As its complex design process structure and large capacity, it has been a problem plagued the industry for this type of tanks level measurement, the commonly used single flange level gauge is limited by the changes of media pressure, temperature, density, and it will cause greater error, Now we often use high-frequency or guided wave radar with a steel rope for comprehensive level measurement, the working principle of radar level gauge measurement as follows:

The radar level gauge can be mounted on a waveguide with an internal diameter of 150.3-161.5 mm.

First, the processing of the guide wave tube:

First, the processing of the guide wave tube:

- Need to drill holes in the guide wave tube, the diameter is 20 mm, the holes between the spacing of 300-400 mm. Holes are the double row of holes.

- After drilling, to remove the inner wall burr, try to ensure the smooth of the inner wall.

- The waveguide tube inner wall roughness requirements Rt20, the general seamless steel pipe roughness cannot meet the requirements, the stainless steel tube is the best choice.

- When welding of the waveguide tube, first pre-remove the welding burr, try to avoid the welding slag enter the weld gap or bonding in the inner wall of the tube. To ensure that the inner wall is smooth and the waveguide is straight.

Second, the installation and connection of the waveguide tube:

- The installation deviation of the waveguide tube is less than + / 0.3 degrees, that is 0.05m/10m.

- The installation of the radar flange level deviation should not be greater than ± degrees.

- The upper flange of the guide wave tube is: DN150, PN16 (connect with the radar).

Post time: 21-09-21