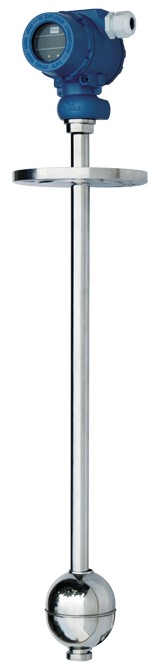

In industrial production, companies use many liquids that are harmful to the environment and the human body. These liquids are also stored in special containers, so it is difficult to measure the liquid level. Let Huitian Instruments and everyone introduce the floating level gauge installed below.Side mounted float level gauge When measuring liquids with side-mounted float level gauges, the bypass pipe top-mounted or side-mounted method is adopted. The main body of the magnetic turning column is provided with a liquid level indicator, a liquid level switch and a liquid level transmitter. The magnetic unit is placed in the floating ball or connected to the floating ball through the ejector rod. When the float-related magnetic unit changes with the liquid level, flip the magnetic color block (magnetic flip board); the magnetic liquid level switch moves in the corresponding liquid position; at the same time, the liquid level sensor outputs a standard change resistance signal under the magnetic force of the float , And then convert the resistance signal into a 4-20 mA current signal output by the transmitter.The level gauge adopts the connector principle. Introduce the liquid in the container into the main pipe of the level gauge. The main float assembly is based on the principle of buoyancy and magnetic coupling. A flip column that can reflect the magnetic phenomenon is attached to the main pipe as a display of the liquid level. As the liquid level in the style tube changes, the level of the float assembly also changes. As a result, the inverted column outside the main pipe reversed 180 degrees. When the liquid level rises, the inverted column changes from white to red, and when the liquid level drops, the inverted column changes from red to white. The red and white border of the display is the actual height of the medium liquid level in the container.Side mounted float level gaugeFeatures of side-mounted float level gaugeWide application range, various installation forms, suitable for the measurement of any medium level and interface; the measured medium is completely isolated from the indicating structure, with good sealing performance, anti-leakage, suitable for high pressure, high temperature, and corrosion conditions of liquid level measurement, and reliability High; on-site indication, remote transmission, alarm control of the whole machine, freely adjustable, complete functions, dual-color indicator light with luminous, continuous and intuitive, eye-catching, wide measurement range, observation direction can be changed arbitrarily; good anti-vibration, can adapt to liquid Large fluctuations in position; simple structure, convenient installation, low maintenance cost; equipped with exquisite magnetic steel corrector, on-site random adjustment.During use, a shut-off valve is installed between the side-mounted floating level gauge and the upper and lower liquid distribution pipes of the container to be tested to open or assemble the level gauge. On the other hand, it is convenient for the liquid level to be maintained. When the upper and lower shut-off valves are closed, the bottom discharge flange of the level gauge can be opened or removed, and the main body of the level gauge can be cleaned by injecting clean water.

When measuring liquids with side-mounted float level gauges, the bypass pipe top-mounted or side-mounted method is adopted. The main body of the magnetic turning column is provided with a liquid level indicator, a liquid level switch and a liquid level transmitter. The magnetic unit is placed in the floating ball or connected to the floating ball through the ejector rod. When the float-related magnetic unit changes with the liquid level, flip the magnetic color block (magnetic flip board); the magnetic liquid level switch moves in the corresponding liquid position; at the same time, the liquid level sensor outputs a standard change resistance signal under the magnetic force of the float , And then convert the resistance signal into a 4-20 mA current signal output by the transmitter.The level gauge adopts the connector principle. Introduce the liquid in the container into the main pipe of the level gauge. The main float assembly is based on the principle of buoyancy and magnetic coupling. A flip column that can reflect the magnetic phenomenon is attached to the main pipe as a display of the liquid level. As the liquid level in the style tube changes, the level of the float assembly also changes. As a result, the inverted column outside the main pipe reversed 180 degrees. When the liquid level rises, the inverted column changes from white to red, and when the liquid level drops, the inverted column changes from red to white. The red and white border of the display is the actual height of the medium liquid level in the container.Side mounted float level gaugeFeatures of side-mounted float level gaugeWide application range, various installation forms, suitable for the measurement of any medium level and interface; the measured medium is completely isolated from the indicating structure, with good sealing performance, anti-leakage, suitable for high pressure, high temperature, and corrosion conditions of liquid level measurement, and reliability High; on-site indication, remote transmission, alarm control of the whole machine, freely adjustable, complete functions, dual-color indicator light with luminous, continuous and intuitive, eye-catching, wide measurement range, observation direction can be changed arbitrarily; good anti-vibration, can adapt to liquid Large fluctuations in position; simple structure, convenient installation, low maintenance cost; equipped with exquisite magnetic steel corrector, on-site random adjustment.During use, a shut-off valve is installed between the side-mounted floating level gauge and the upper and lower liquid distribution pipes of the container to be tested to open or assemble the level gauge. On the other hand, it is convenient for the liquid level to be maintained. When the upper and lower shut-off valves are closed, the bottom discharge flange of the level gauge can be opened or removed, and the main body of the level gauge can be cleaned by injecting clean water.

Post time: 21-09-21