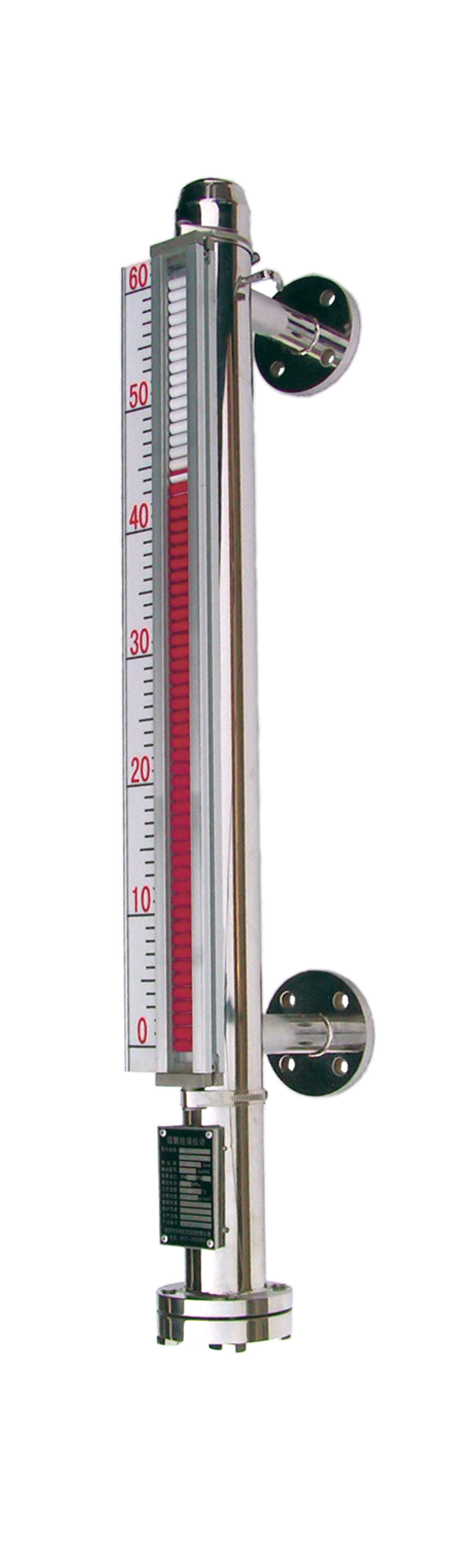

In many industries, it is often used to obtain flammable, explosive, corrosive and toxic liquids. These liquids need to be stored in special containers. So how to detect the quantity of these liquids? Let’s let Huikoda Instruments talk to you about the side-mounted magnetic levitation level gauge. Side mounted magnetic float level gaugeThe side-mounted magnetic suspension level gauge is used for the detection of liquid medium level in various pressure (or open) liquid storage equipment (towers, cylinders, tanks, spherical vessels and boilers) in industrial processes. It can display the working conditions and liquid level height of various liquids on site. Equipped with a liquid level transmitter, the position signal of the liquid level can be transmitted over a long distance. Realize the automatic control and measurement of liquid level through some kind of electrical device.The level gauge is a reliable and safe measuring instrument. Due to the isolated closed structure with magnetic coupling. It is especially suitable for the detection of flammable, explosive, corrosive and toxic liquid level. Thus, the liquid level detection method in the original complex environment becomes simple, reliable and safe. The utility model has the characteristic of direct reading on site. There is no need for multiple sets of level gauge combinations. There are monomers for full-scale measurement. The device has the advantages of small opening, clear display, eye-catching, and intuitive reading. When the level gauge is directly equipped with a display instrument, the intermediate transmission of the system signal detection can be eliminated, and the transmission accuracy can be improved.Side mounted magnetic float level gaugeWorking principle of side-mounted magnetic float level gaugeThe side-mounted magnetic suspension level gauge adopts the connector principle. Introduce the liquid in the container into the main pipe of the level gauge. The main float assembly is based on the principle of buoyancy and magnetic coupling. A flip column that can reflect the magnetic phenomenon is attached to the main pipe as a display of the liquid level. As the liquid level in the style tube changes, the level of the float assembly also changes. As a result, the inverted column outside the main pipe reversed 180 degrees. When the liquid level rises, the inverted column changes from white to red, and when the liquid level drops, the inverted column changes from red to white. The red and white border of the display is the actual height of the medium liquid level in the container.Precautions for the application of side-mounted magnetic float level gaugeInstall a shut-off valve between the side-mounted magnetic float level gauge and the upper and lower separation pipes of the container to be tested to open or assemble the level gauge. On the other hand, it is convenient to maintain the liquid level. When the upper and lower shut-off valves are closed, the liquid level The discharge flange at the bottom of the gauge can be opened or removed, and the main body of the level gauge can be cleaned by injecting clean water.Side mounted magnetic float level gaugeInstall the level gauge, flange centerline verticality ∠4&Permil; when the measuring range of the level gauge is greater than 3 meters, you must consider adding a middle reinforced flange (or climbing ear) as a fixed support to improve the strength.The cross-sectional area of the core wire between the remote level gauge transmitter and the secondary instrument should be greater than 0.8mm2. When placed in parallel with the AC power supply, keep a distance of at least 20 cm. It is best to pass through the iron pipe alone or to lay it with a shielded two-core cable. The shield can only be grounded at one end.

Side mounted magnetic float level gaugeThe side-mounted magnetic suspension level gauge is used for the detection of liquid medium level in various pressure (or open) liquid storage equipment (towers, cylinders, tanks, spherical vessels and boilers) in industrial processes. It can display the working conditions and liquid level height of various liquids on site. Equipped with a liquid level transmitter, the position signal of the liquid level can be transmitted over a long distance. Realize the automatic control and measurement of liquid level through some kind of electrical device.The level gauge is a reliable and safe measuring instrument. Due to the isolated closed structure with magnetic coupling. It is especially suitable for the detection of flammable, explosive, corrosive and toxic liquid level. Thus, the liquid level detection method in the original complex environment becomes simple, reliable and safe. The utility model has the characteristic of direct reading on site. There is no need for multiple sets of level gauge combinations. There are monomers for full-scale measurement. The device has the advantages of small opening, clear display, eye-catching, and intuitive reading. When the level gauge is directly equipped with a display instrument, the intermediate transmission of the system signal detection can be eliminated, and the transmission accuracy can be improved.Side mounted magnetic float level gaugeWorking principle of side-mounted magnetic float level gaugeThe side-mounted magnetic suspension level gauge adopts the connector principle. Introduce the liquid in the container into the main pipe of the level gauge. The main float assembly is based on the principle of buoyancy and magnetic coupling. A flip column that can reflect the magnetic phenomenon is attached to the main pipe as a display of the liquid level. As the liquid level in the style tube changes, the level of the float assembly also changes. As a result, the inverted column outside the main pipe reversed 180 degrees. When the liquid level rises, the inverted column changes from white to red, and when the liquid level drops, the inverted column changes from red to white. The red and white border of the display is the actual height of the medium liquid level in the container.Precautions for the application of side-mounted magnetic float level gaugeInstall a shut-off valve between the side-mounted magnetic float level gauge and the upper and lower separation pipes of the container to be tested to open or assemble the level gauge. On the other hand, it is convenient to maintain the liquid level. When the upper and lower shut-off valves are closed, the liquid level The discharge flange at the bottom of the gauge can be opened or removed, and the main body of the level gauge can be cleaned by injecting clean water.Side mounted magnetic float level gaugeInstall the level gauge, flange centerline verticality ∠4&Permil; when the measuring range of the level gauge is greater than 3 meters, you must consider adding a middle reinforced flange (or climbing ear) as a fixed support to improve the strength.The cross-sectional area of the core wire between the remote level gauge transmitter and the secondary instrument should be greater than 0.8mm2. When placed in parallel with the AC power supply, keep a distance of at least 20 cm. It is best to pass through the iron pipe alone or to lay it with a shielded two-core cable. The shield can only be grounded at one end.

Post time: 21-09-21