Flow meter is an important component of energy metering instruments, no matter water, artificial gas, natural gas, steam or oil, it will commonly use electromagnetic flowmeters, or other flowmeters, such as metal tube rotameter, orifice plate flowmeter, turbine flowmeter, vortex flowmeter and so on. They are all indispensable tools for energy management and economic accounting. So it is quite necessary to master the rich knowledge on instrument maintenance. The following information describes how to maintain the flow meter instrument.

(Metal tube rotameter)

Maintenance

1. Always observe the sensor power cable and transmission cable (or wire) for damage, aging phenomenon, and protect the rubber sheath outside the cable.

2. Regularly (usually six months) scrub the electrode surface with a soft cloth, remove dirt or sediment.

3. Remove the debris from the upstream section of the sensor.

Troubleshooting and solutions

1. Liquid does not flow but the output:

- There are open circuit connection between the converter and signal transmission cable;

- Circuit exist in the connection of signal cable and the electrode;

- Electrode surface contamination or deposition of insulating layer;

- Poor grounding or open circuit.

Solution:

- Connect the cable;

- Open the sensor, re-connected;

- Scrub electrode surface;

- Connect the grounding line.

(Electromagnetic flowmeter)

2. Liquid flow but no output:

- Converse connection of the signal transmission cable Two-core wire between the converters ;

- Power is not connected or poor contact;

- Leakage of sensor instrument pipeline, shell, end surface.

Solution:

- Invert the head;

- Connect to the power supply and maintain good contact;

- Repair the sensor.

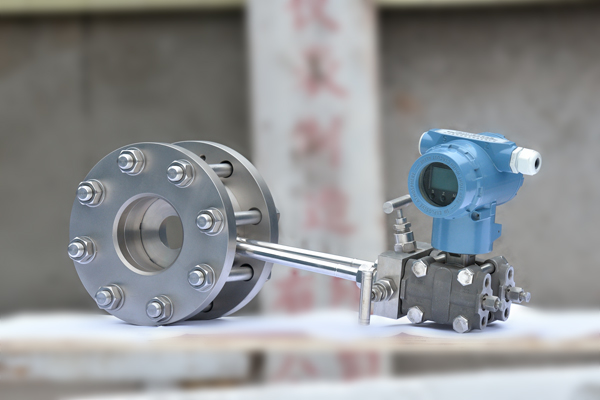

(Orifice plate flow meter)

3. Unstable output :

- Instability of flow field ;

- Liquid that through the sensor containing gas, large solid block;

- Virtual connection of electrical connection;

- Poor grounding;

- Electrode leakage

Solution:

- Modification of the channel, or increase the installation of sensors;

- Normal phenomenon;

- Check the wiring, then connect it;

- Connect the grounding line;

- Repair the sensor.

(Vortex flowmeter)

4. Too large deviation:

- Zero point is too high;

- Not completely filled with liquid;

- Too large of power supply distortion;

- Poor grounding.

Solution:

- Re-adjust the zero point;

- Improve the channel conditions, let the sensor always full of liquid;

- Improve the power supply conditions, make it in line with normal working conditions;

- Connect the grounding line.

Post time: 21-09-21