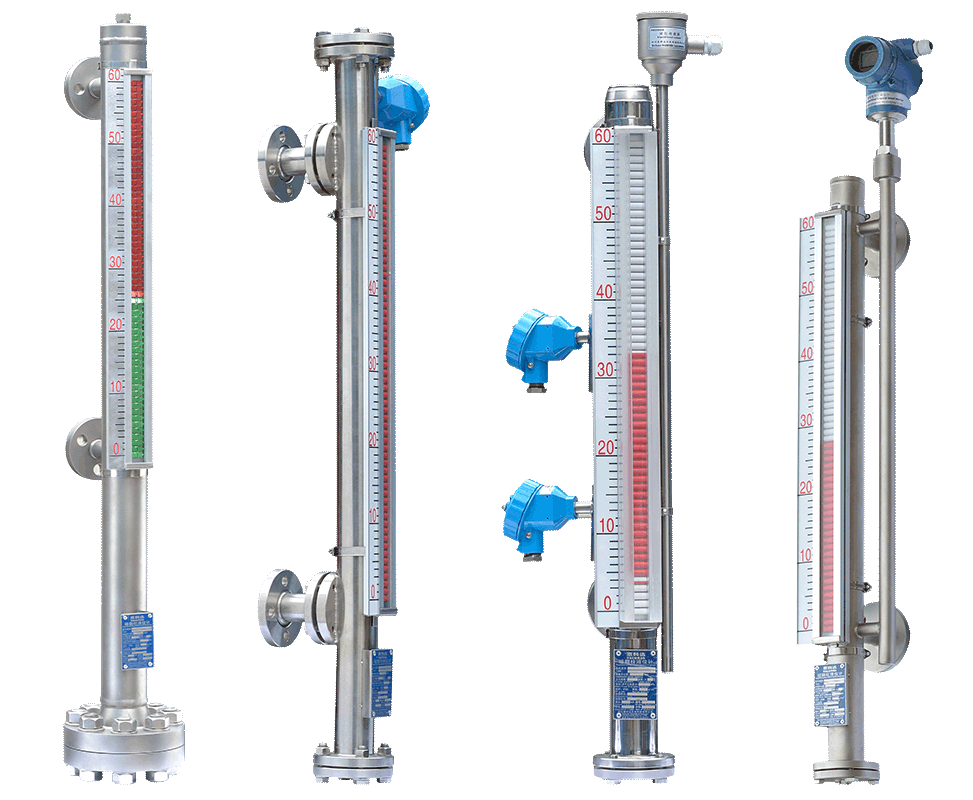

Magnetic flap level gauge: also called magnetic float level gauge, magnetic flip column level gauge.Principle: Using the principle of communicating device, connect with the container through gas and liquid phase link flanges. According to the principle of buoyancy and magnetic coupling, the magnetic float in the measuring cylinder (that is, the communicating device) drives the two-color magnetic flap on the external display of the measuring cylinder to flip with the increase (decrease) of the measured liquid level. When the liquid level rises, the magnetic float drives the turning column to rotate 180°, displaying red or green; when the liquid level drops, the magnetic float drives the turning column to rotate 180° in reverse, displaying white. The height of the red band (or green band) is the height of the measured liquid surface, which achieves the purpose of measuring and displaying the position of the measured liquid (interface) surface.Each magnetic flap is a two-color axially symmetric structure. The distance between the two magnetic flaps is 10mm. White and red (green) are used to indicate the gas phase and liquid phase. The junction of red (or green) and white is The boundary between the liquid phase and the gas phase. The level gauge can measure both the liquid level and the interface of two different density media.Features:The parts and materials of the high temperature and high pressure magnetic flap level gauge are made of 304, 316L, 321, 1Cr18Ni9Ti, 0Cr18Ni9, 00Cr17Ni14Mo2, titanium alloy and imported high-quality electronic components. The product has high reliability, good stability, durability, and high corrosion resistance. . Its characteristics are very significant:1. The structure is simple, sturdy, reliable, durable, almost no maintenance workload, and can be installed and used outdoors for a long time; 2. The measured medium is completely isolated from the display part of the liquid level gauge, the liquid level sensor, and the magnetic switch; 3. Work Wide pressure range: withstand pressure from vacuum to 42MPa; 4, wide working temperature range, suitable for -190~425℃; 5, not affected by the physical and chemical state of the measured medium. Such as: the medium’s conductivity, dielectric constant, foam, pressure, temperature, evaporation, boiling, bubbles, etc. Widely used in various strong and weak corrosive, flammable and explosive, toxic, strong radioactive, agitated, dirty liquid level and interface measurement; 6, optional single pole single throw (SPST) single pole double throw (SPDT) passive Bistable magnetic switch, realize high and low liquid level, interface control or alarm. The number of magnetic switches is not limited. 7. Optional reed switch liquid level sensor or capacitive two-wire liquid level sensor, output 4-20mADC (or with HART protocol) signal, realize remote centralized measurement and control. 8. The two-wire liquid level sensor can be equipped with 0.56’ LED digital display, which is convenient for night observation.technical parameter:▲Installation center distance: 150-6000mm ▲Medium density: greater than 0.45g/cm3 ▲Nominal pressure: PN50-PN420 (×0.1MPa) section selection▲Material of level gauge: 304, 316L, 321, 1Cr18Ni9Ti, 0Cr18N-i9, 00Cr17Ni14Mo2, titanium alloy, etc. (other materials can be ordered through negotiation) ▲Working temperature: -190~425℃▲Installation interface form: flat welding flange, external thread, internal thread, welded pipe, loop flange, butt welding flange ▲The top structure of the main pipe: welding cap, welding cap with M14×1.5 screw plug, flange, Flange with M14×1.5 screw plug, welding cap with DN20 flange, flange with DN20 flange, welding cap with exhaust valve, flange with exhaust valve▲The bottom structure of the main pipe: flange cover, flange with drain plug, flange with DN20 welded pipe, with DN20 flange, with needle drain valve or ball valveMagnetic turning column display: Type A: Aluminum alloy high-strength plastic turning pillar Type B: Aluminum alloy, aluminum turning plate Type C: Corrosion-resistant PVC, high-strength plastic turning pillar Type D: Corrosion-resistant polypropylene, high-strength plastic turning pillar Type E: Aluminum Alloy, LED display Type F: Polypropylene, LED display▲Protection level: IP65Common faults and solutions of magnetic flap level gauge floats. Magnetic flap level gauges often fail in practical applications. Some of these faults are caused by a single component failure, and some are caused by multiple component failures at the same time. of. The common failures of magnetic flap level gauges and their causes are as follows.1. Abnormal display on the display panel usually causes the following reasons:1. The design of the gap between the flap and the guide rail is unreasonable or too small, resulting in excessive friction and the flap does not turn over;2. The distance between the display panel and the buoy is too large, and the magnetic steel driving force of the buoy is insufficient, which causes the flip sheet to not turn over;3. The magnetic steel in the flip is too small or the magnetic force disappears, causing the flip not to flip or to flip abnormally;4. Impurities such as water or dust penetrate into the display panel, making it difficult to turn the film over;5. The ambient temperature is too low, causing the medium to freeze, the float cannot move, and the flip sheet cannot display the liquid level normally.2. The local display is normal, but the remote display is abnormalGenerally speaking, this failure usually has the following reasons,1. The domestic glass tube reed switch is fragile, and the reed switch is short-circuited or opened, which will cause abnormal remote transmission;2. Resistance welding;3. The metal contact gap of the reed switch is very small. When the temperature of the medium is too high, the metal flakes expand when heated, and the closed state is easy to appear;4. The pressure exceeds the rated value, causing damage to the switch.Third, the remote transmission and the magnetic flap will not moveThis failure phenomenon is usually caused by an abnormal float, and has the following two manifestations:Phenomenon 1: The float is stuck, causing incorrect indications on the display panel.Fault analysis, the float in the magnetic flap level gauge is stuck, usually due to the following reasons:1. When the float is used for a period of time, the float may get stuck due to the presence of impurities and cannot rise or fall;2. The installation angle of the buoy is less than 87 degrees, which causes tilt and affects the up and down movement of the buoy;3. The float is stuck due to its own magnetic adsorption of iron filings or other dirt;4. The ambient temperature is too low, causing the medium to freeze and the float cannot move.Phenomenon 2: The float is damaged, resulting in incorrect indications on the display panel.Failure analysis, damage to the float in the magnetic flap level gauge, usually due to the following reasons:1. Due to the incorrect strength design of the float, it dents inward and becomes deflated when subjected to overpressure;2. There is no penetration or missing welding at the welding place, which causes the weld to crack when the float is under pressure, and the float enters water;3. The float is unusable due to demagnetization due to long-term use or long-term high-temperature use;4. The magnetic steel in the float is loose, causing the float to fail to work.Through the analysis of the common faults of the magnetic flap level gauge, the solution to the problem is basically found. Because the cause of the fault is found, the problem is half solved. According to the fault and its cause, the targeted treatment can be done. .

Post time: 21-09-21