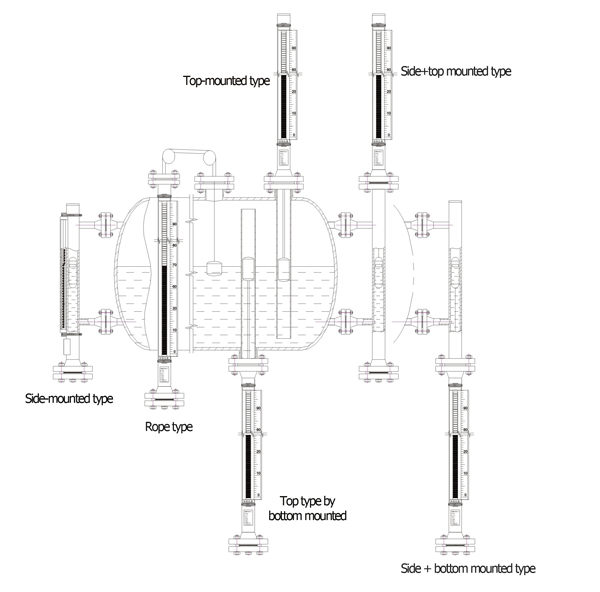

Magnetic flap level indicator has two kinds of installation, side loading and top loading, no matter which way it can be equipped with remote transmission device, You can make the liquid level indicator not only display the liquid level on the spot, but also remote monitoring liquid level. And then the this type of liquid level indicator can be called remote-type magnetic flap level indicator. Now we are talking about the assembly process for a brief introduction.

(Application of magnetic level indicator)

1. There can not have magnetic material around theMagnetic flap level gauge body, and can not fix by the wire, or it will affect thenormal workof the magnetic flap level gauge;

2. If the users themselves usethe heating pipe, itmust use non-magnetic materials, like the copper tube. The heat tracing temperature is determined according to the medium condition.

3. Magnetic flap level gauge must be installed vertically, it should be equipped with ball valve between the magnetic flap level gauge and the containerfor easy maintenance and cleaning;

4. Medium should not contain solid impurities or magnetic substances, so as to avoid jamming on the float;

5. Before use shouldusethe magnetto set the ball red below the zero position, and the other ballsset white;

6. Open the bottom flange and insert the magnetic float (Note: let the heavyand the magnetic end up, it can not flip.);

7. When commissioning, it should first open the upper catheter valve, and then slowly open the lower valve, so that let medium smoothly into the main tube. Observe whether the magnetic red&white ball reversal normal, and then close the lower tube valve, open the drain valve, let the main tube of liquid level down, three times according to this method, if it is indeed normal, you can put into operation (corrosive and other special liquid is excluded);

(Installation of magnetic level indicator)

8. Should be based on medium conditions, to clean the main pipe to remove impurities from time to time;

9. For more than a certain length of level gauge(ordinary type> 3 m, anti-corrosion type> 2 m),

It need to increase the middle reinforcement flange or ear climbing for fixed support to increase the strength and to overcome their own weight;

10. The installation location of magnetic flap level gauge should avoid or be away from the import and export of materials, affecting the accuracy of liquid level measurement;

11. When equipped with remote instrumentation (UB or UK), you need to do as the following:

A. Should be remote instrument close to the main pipe of the level gauge, and then fixed with stainless steel hoop(disable iron);

B. The sensing surface of remote instruments should be oriented and close to the main pipe;

C. Far-distance instrumentation zero point should be at the same level with the zero point of level indication ;

D. It’s better individually wear protective tube laying or laying with a shielded two-core cable at the connection between the remote instrumentation and display instrumentation or industrial control machine;

E. After the wiring hole of the junction box is laid, it should be well sealed so as to avoid the intrusion of rain water, moisture and so on. The junction box should cover in time after finishing the maintenance or debugging.

We are concerned about the products in all aspects.Do ourbest to solvethe problems which everyone’s attentionto.Pleasecontinue to focus on the Vacorda instrument.Weare willing to help to solve the problems. We look forward to the visit!http://www.vacorda.com

Post time: 21-09-21