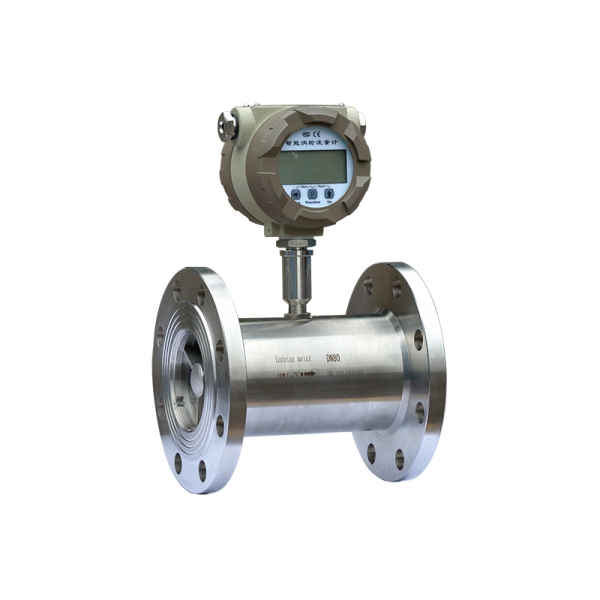

The manufacturer of VacordaDN80 vortex flowmeter mainly produces various flowmeters, including vortex flowmeters, electromagnetic flowmeters, steam flowmeters and turbine flowmeters.The working principle of VacordaDN80 vortex flowmeter manufacturerThe vortex flowmeter is developed and produced according to the Karman vortex principle. It is mainly used for the flow measurement of gas, liquid, steam and other medium fluids in industrial pipelines. It has the characteristics of small pressure loss, large measuring range and high accuracy. When measuring volume flow under working conditions, it is almost unaffected by parameters such as fluid density, pressure, temperature and viscosity. There are no moving mechanical parts, so the reliability is high and the maintenance is small. The instrument parameters can be stable for a long time. The vortex flowmeter adopts piezoelectric stress sensor, which has high reliability and can work in the working temperature range of -20 ~ 250. There are analog standard signals and digital pulse signals, which are easy to use with digital systems such as computers. It is an advanced and ideal measuring instrument.Parameters and requirements of DN80 vortex flowmeterMeasuring medium: gas, liquid and steamConnection mode: flange card type, flange type, plug-in typeDiameter specifications: 25, 32, 50, 80, 10 are flange mounting diametersFlange connection type diameter is 100, 150, 200Flow measurement range The Reynolds number of the normal measurement flow range is 1.5104 ~ 4106; gas 5 ~ 50m/s; liquid 0.5 ~ 7m/sMeasurement accuracy is 1.0 and 1.5The measured medium temperature is: normal temperature 25~100, high temperature 25~150-25~250Output signal pulse voltage output signal high level 8 ~ 10v low level 0.7 ~ 1.3VPulse duty cycle is about 50%, transmission distance is 100mPulse current transmission 4 ~ 4 ~ 20mA signal, transmission distance 1000m m.The working environment temperature of the instrument is: -25 ~ 55, the humidity is: 5~90% RH50Material stainless steel, aluminum alloyPower DC24V or lithium battery 3.6VThe explosion-proof grade is intrinsically safe Iaibt3-T6, and the protection grade is IP65Common faults of DN80 vortex flowmeterCommon failures of vortex flowmeter nine. According to the specification, the DN50 vortex flowmeter has a liquid flow range of 3-50m3/h. Our calibration results on the oil flow standard device show that 10-50 m3/h meets the accuracy requirements, but the accuracy below 10m3/h is unqualified. How should this flowmeter be evaluated?In the vortex juice specification, the indicated flow range is the flow range for a specific reference medium, such as liquid water at room temperature. When used in other media, the available flow range will vary with the viscosity and density of the media. Since the oil flow standard device uses diesel with a higher viscosity and lower density than water as the calibration medium, the lower limit flow rate of the flowmeter will generally increase accordingly, thus narrowing the available flow range. Therefore, when calibrating on the oil flow calibration device, it is normal that the small flow performance of the vortex flowmeter deteriorates. It is not difficult to infer that if liquefied petroleum gas (such a low-viscosity medium) is used to calibrate the vortex juice, the effect will be better than water in turn. 1. The measurement range of the vortex flowmeter is very wide, generally 101, but the lower limit of measurement is limited by many factors: Re10000 is the most basic condition for the vortex flowmeter to work. In addition, it also generates a response signal through the eddy current, the vortex frequency f is also very small, which brings difficulties to signal processing. The upper limit of the measurement is the frequency response of the sensor and the frequency limit of the circuit. Therefore, the flow rate range must be calculated and checked during design, and selected according to the flow rate of the fluid. The environmental conditions of the place of use are complicated. In addition to ambient temperature, humidity and atmosphere, electromagnetic interference should also be considered.2. Vibration is also the enemy of this type of instrument. Therefore, attention should be paid to avoid mechanical vibration, especially the transverse vibration of the pipeline (vibration perpendicular to the axis of the pipeline and the axis of the vortex generator), which cannot be suppressed and eliminated in the flowmeter structure design. Since the vortex signal is also very sensitive to the flow field, it is not suitable when the length of the straight pipe cannot guarantee the flow conditions required to stabilize the vortex street. Even the capacitive and ultrasonic types with strong vibration resistance can ensure that the fluid is a fully developed unidirectional flow and cannot be ignored.

3. The temperature of the medium has a great influence on the performance of the vortex flowmeter. If the pressure stress vortex flowmeter cannot be used for a long time at 300C, its insulation resistance will drop sharply from 10-100 at normal temperature to 1-101, and the output signal will become smaller, resulting in poor measurement characteristics. In the measurement system, the sensor and the converter should be installed separately to avoid long-term high temperature affecting the reliability and service life of the instrument. The vortex flowmeter is a relatively new type of flowmeter, which is in the development stage and not very mature yet. If you choose improperly, its performance will not be played well. Only after reasonable selection and correct installation, careful and regular maintenance during use, continuous accumulation of experience, and improvement of the predictability of system failures and the ability to judge and deal with problems can achieve satisfactory results.

Post time: 21-09-21