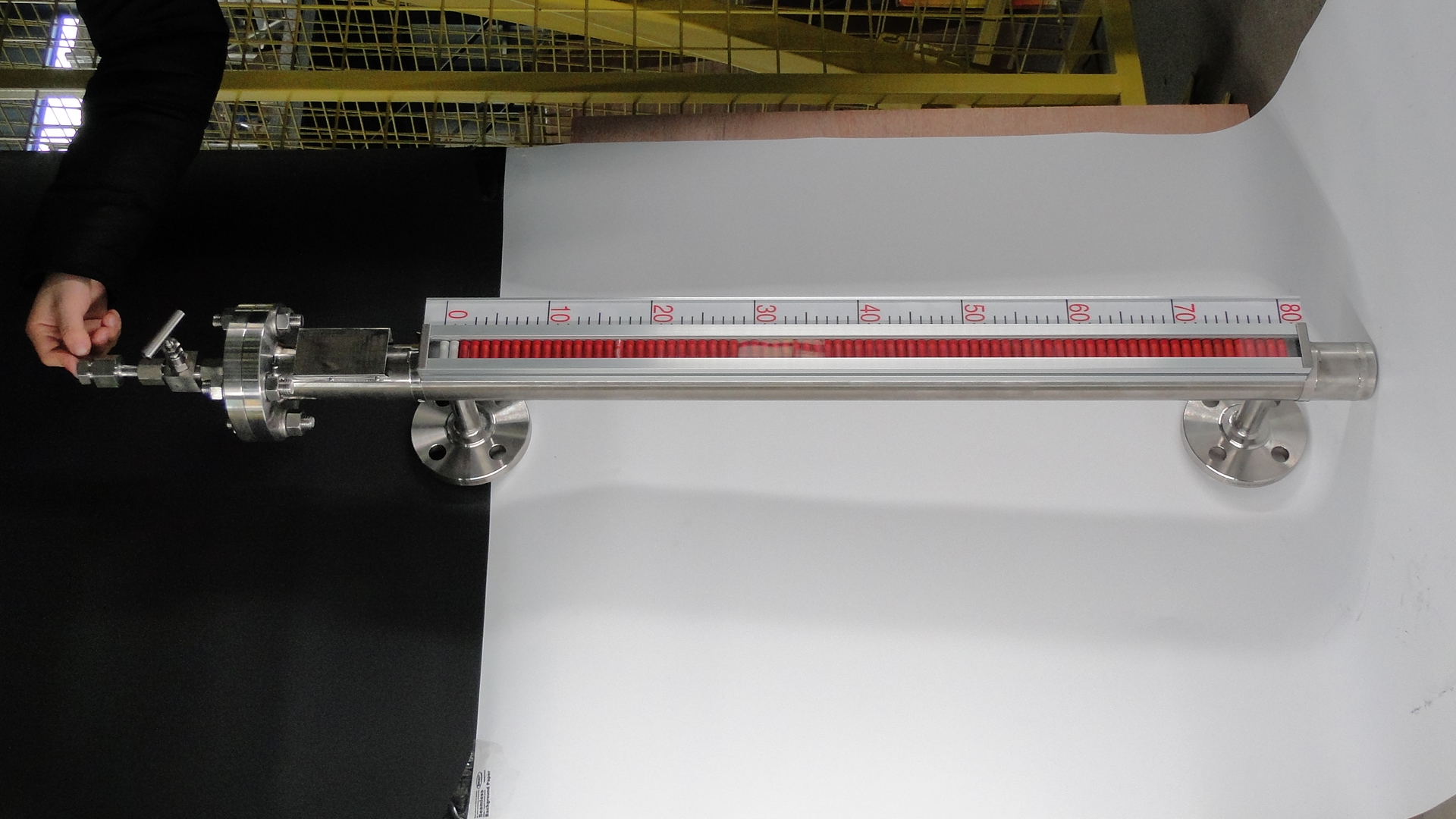

The magnetic flap level gauge is an instrument that can measure the level of various media. At present, it is used in many industries, so what are the parameters of the magnetic flip plate level gauge? What are the characteristics of the magnetic flap level gauge? The following Huikeda instruments will give your friends a detailed introduction.Magnetic flap level gauge parametersWhat are the parameters of the magnetic flap level gauge?Measuring range: 3-15 mmMeasurement accuracy: 10 mmResolution: 0.1Blind area: 10.Pressure: 1.6Power supply voltage: 220 VAnalog output: 4-20 mA.Measuring tube material: stainless steel.Protection level: IP 65Custom processing: YesShape size: 1000 mmWeight: 1 kg.Measuring method: Magnetic flip-plate level gauge.Installation form: flange connection.Media density: as required.Medium temperature: 100 degreesPower supply: 24VOutput mode: 4-20mA.Explosion-proof grade: IP 65Features of magnetic flap level gauge1. It is suitable for liquid level measurement of the liquid medium in the container. In addition to on-site display, it can also be equipped with remote control transmitters, liquid level controllers and other functions.2. The display is intuitive and eye-catching, and the display direction can be changed according to user requirements.3. The measurement range is large, and it is not limited by the height of the container.4. The display component is completely isolated from the measuring medium, and the sealing performance is good, reliable and safe.5. Simple structure, convenient installation and simple maintenance.6. Corrosion-resistant and explosion-proof.Magnetic flap level gauge parametersThe problems that should be paid attention to in the installation of the liquid level gauge and its application in specific applications1. The installation position of the magnetic flip plate level gauge should be avoided or far away from the entrance and exit of the material medium to avoid rapid changes in the local area of the liquid level, which will affect the accuracy of the liquid level measurement.2. When users use their own heating pipes, they must choose non-magnetic conductive materials such as copper pipes, and determine the following temperatures according to the condition of the medium.3. The medium should not contain solid impurities or magnetic substances, so as not to block the float.4. Before using the level gauge, the sub-zero ball should be set to red, and the other balls should be set to white, and equipped with a calibrated magnet.5. It is forbidden to place magnetic conductive materials around the body of the level gauge, and it is forbidden to fix the wire, otherwise it will affect the normal operation of the magnetic suspension level gauge.6. The installation of the magnetic disc level gauge must be vertical, and a ball valve should be installed between the magnetic float level gauge and the water pipe of the container for easy maintenance and cleaning.7. Open the bottom flange and load the magnetic levitation (Note: the magnetic head of the heavy end is up at one end and cannot be inverted).8. When debugging, open the upper pilot valve first, and then slowly open the lower valve, so that the medium can smoothly enter the main duct (the medium should avoid the rapid impact of the medium on the float, which will cause the float to fluctuate and affect the display accuracy). Observe whether the magnetic red and white ball flips normally, then close the lower pilot valve, open the sewage valve, and the magnetic flip plate level gauge makes the main liquid level drop. According to this method, the liquid level in the main pipe is reduced by 3 times. If it is normal, it can be put into use (except for corrosive liquids and other special liquids).

Post time: 21-09-21