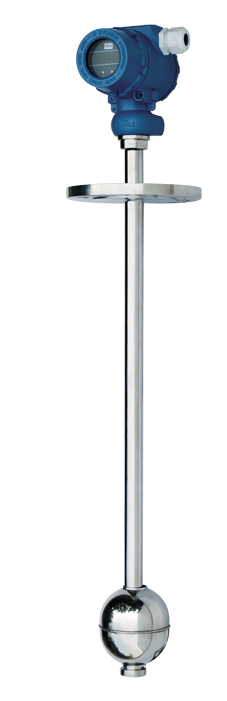

At present, many industries need to use the equipment of explosion-proof airbag level gauge, as long as there is enough understanding of explosion-proof airbag level gauge, it can play a greater role. What are the working principle of the explosion-proof airbag level gauge and the characteristics of the product?Explosion-proof float level gaugeThe explosion-proof airbag level gauge is composed of three parts: a magnetic levitation ball, a sensor and a transmitter. When the magnetic levitation ball moves up and down along the pipe according to the level of the liquid level, the magnetic steel in the levitation ball adsorbs the clarinet at the corresponding position in the sensor, so that the total resistance (or voltage) of the sensor changes, and the changed resistance is changed with a transmitter) or The voltage) signal is converted to a 4-20mA current signal. In addition, by setting the upper and lower limit alarms on the display, the position of the liquid level can be controlled.Explosion-proof float level gaugeFloat level gaugeThe float level gauge uses a magnetic levitation ball as the measuring element, and the resistance in the sensor changes linearly through magnetic coupling. The resistance change is converted into a 4-20mA standard current signal through an intelligent converter, and the percentage of the liquid level, 4~ 20mA current and liquid level value, remotely supplied to the control room. This instrument is suitable for sewage treatment in petroleum, chemical, electric power, light industry, medicine and other industries and the measurement of medium level in various atmospheric and pressure vessels, especially for underground Liquid level measurement of storage tanks and oil storage tanks.The working principle of explosion-proof float level gaugeThe explosion-proof airbag level gauge consists of two parts: a liquid level sensor and an intelligent HART board (current converter). The airbag and the liquid level change synchronously. By controlling the suction and cutoff of the clarinet, the resistance in the sensor changes linearly, and the change in resistance passes The converter reaches the standard of 4-20mA.Product features of explosion-proof float level gaugeIntelligent electronic components are composed of a motherboard and an LCD screen. Press the button on the spot to adjust the stroke and zero point. It can communicate with the smart instrument on both sides through a HART communication manual operator or a microcomputer without interrupting the output signal. The instrument measurement, process parameters, equipment structure, calibration, and diagnostic information can be passed through HART in explosion-proof or places where the instrument cannot be easily disassembled and assembled. Protocol access or change is through two-way communication with the host through the distributed control system using HART protocol; because of the EEPROM, data will not be lost due to power failure.Explosion-proof float level gaugeTechnical parameters of explosion-proof float level gaugeMeasuring range: 0~3500mm; Supply voltage: 12~36V DC; Output signal: Overlap digital signal on 2-wire 4~20mA.DC, users can choose square root or linear output; Load resistance: 250; Measurement accuracy 10mm ; Ambient temperature: -40~80; Working temperature: -20~120; Nominal pressure 1.6MPa; Flange reference: A: JB/T82.1-94 (flat flange) DN100 PN1.6 ball 90; (b) B: JB/T82.1-94) flat flange) DN80 PN0.6 ball 76; medium density 0.65 g/cm-3; medium viscosity 0.015PaS; wetted material: stainless steel; protection grade: IP65; explosion-proof grade: ct4-ct6. Explosion-proof airbag level gauge is a common equipment. After reading the above introduction, if you want to know more, please consult Huikeda’s instrument website directly.

Post time: 21-09-21