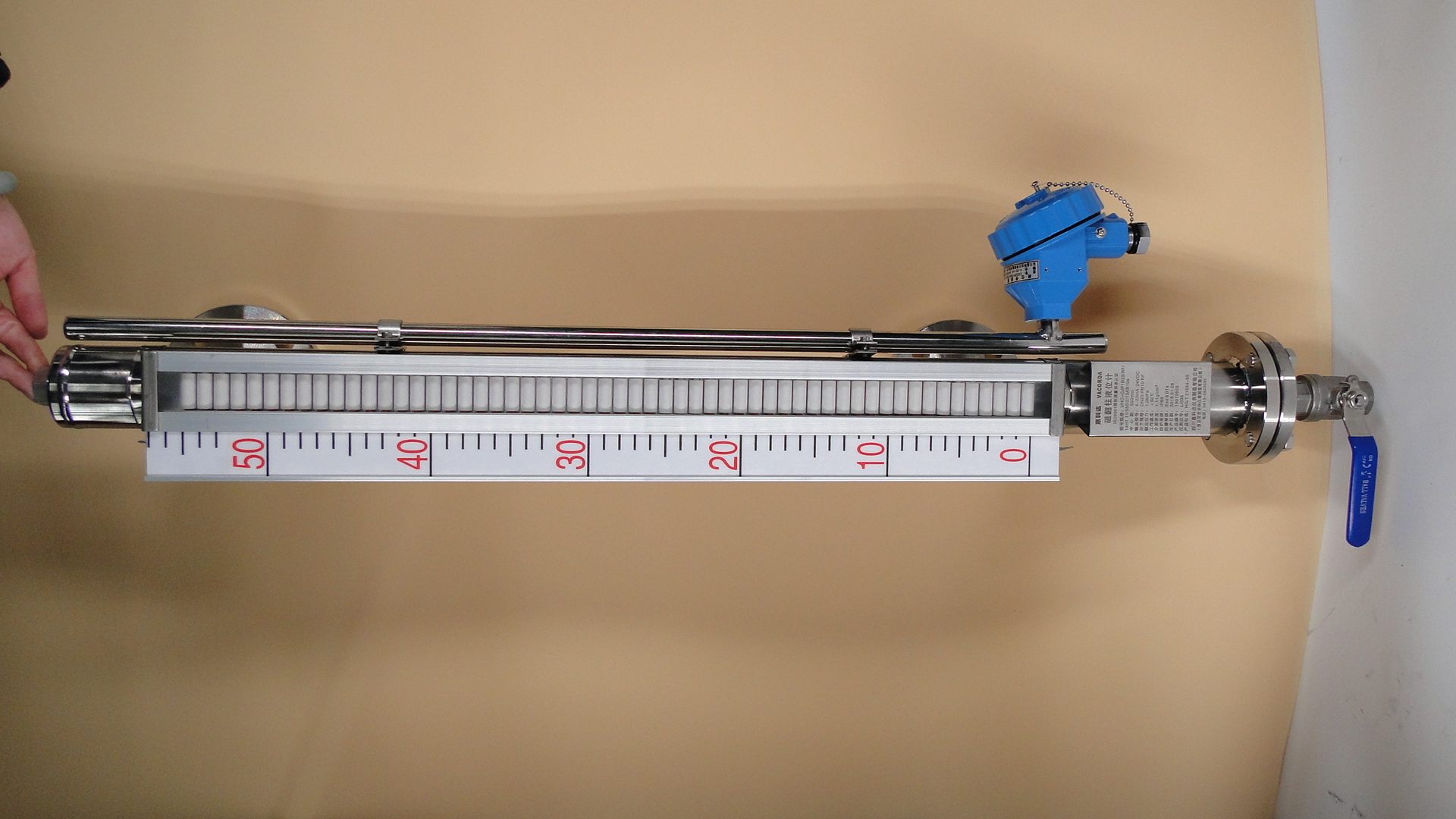

The magnetic turning column level gauge is mainly composed of float, magnetic float, turning sheet, display panel, display panel end cover, drain valve, vent valve, connecting flange, (hexagonal plug), (flat welding cap), etc. . You may have noticed that in the organizational structure of our magnetic flip-column level gauge, there is a drain valve at the bottom and a vent valve at the top. What role do these two components play?After our magnetic turning column level gauge has been in operation for a period of time, a lot of sediment will start to accumulate under the float of the magnetic turning column level gauge, and even our floats will be contaminated with dirt, which will affect The normal measurement of our magnetic flip-column level gauge. In addition, after a long period of use, if the product fails, it needs to be repaired, so it becomes very important to eliminate the sediment in the float!At this time, the drain valve we installed has played a role. We first close the upper and lower shut-off valves connected to the measurement storage tank, let our magnetic flap level gauge stop, and then open the drain valve at the bottom of it. The contents of the pontoon are clear and clean, which solves the problem.The function of the vent valve is that when the dirt left by some medium is very stubborn, it is obviously impossible to remove it naturally. At this time, a water pipe is connected to the vent valve to fill the interior with clean water. Generally, the interior of the float can be flushed. Clean

Post time: 21-09-21