Turbine flowmeter is a very common type of flow instruments, this flow meter can measure a variety of gases and liquids. It uses a new intelligent design, it can maintain high-precision measurements. The turbine flowmeter has excellent performance and long service life, and it also has a strong anti-interference ability. When use the turbine flowmeter, it may encounter a variety of electromagnetic interference, if the anti-interference ability of the flowmeter is not good enough, it may affect the measurement accuracy of the flow meter.

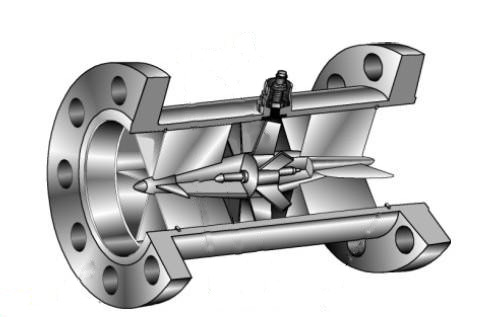

Fluid flow through the sensor housing, the impeller blade and the flow direction has a certain angle, the momentum of the fluid makes the blade has a rotating torque to overcome the friction torque and fluid resistance and then the blade rotate. After the torque balance and speed be stable, under certain conditions, the speed is proportional to the flow rate. Because of the magnetism of the blade, it is in the magnetic field of the signal detector. The rotating blade cuts the magnetic flux, which periodically changes the magnetic flux of the coil, so that the two ends of the coil can induce the electric pulse signal. This signal through the amplification amplifier shaping, forming a certain amplitude of the continuous rectangular pulse wave can be far to the display instrument, showing the fluid flow and the cumulative amount of time.

The power consumption of the turbine flow meter is small, and it adopt the stainless steel structure, so it can ensure the strong anti-corrosion properties during the work situation, and for some corrosive media, turbine flowmeter can well measure the flow, it will not be limited. The turbine flowmeter size is very small, when a failure occurs, it is easy to disassemble the flow meter, and timely repair and cleaning. For more information about the types of flow meter, please continuous concerning our official website:www.vacorda.com

Post time: 21-09-21