Corrosion Protection UQD Electric Internal Float Level Transmitter Float Level Meter

Overview

UQD series electric internal floating ball liquid level transmitter (hereinafter referred to as transmitter) is suitable for continuous measurement of various high temperature, viscous and dirty liquid levels. It can be widely used in petroleum, chemical, metallurgy and pharmaceutical industries.

The transmitter has a moving coil type field indication (analog type) and a liquid crystal numerical display (with HART intelligent type)

It can be programmed through the operator or through the converter and the computer with the HARTTran_V3.70D software installed. Moreover, the instrument configuration settings (zero point and measurement range) can be set through the field operation buttons, and the data can be displayed on the field LCD.

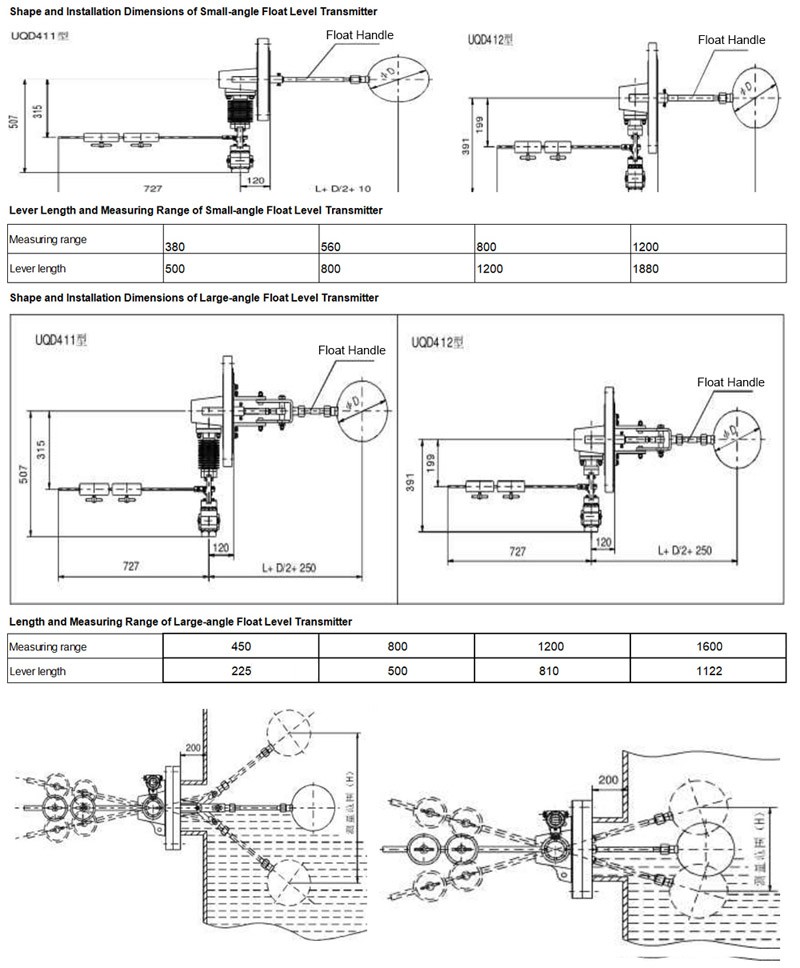

The transmitter is divided into large-angle type and small-angle type according to different structures, and the maximum operating angle of the float is 80° and 35°, respectively.

Working Principle

The liquid transmitter is composed of two major parts: the measurement sensing mechanism and the electric transmission (meter head). The measurement sensing mechanism is composed of the measuring float ball, the float ball rod, the counterweight and the balance rod to form a moment balance mechanism, so the float ball can freely move up and down with the change of the liquid level. When the liquid level changes, the position of the float ball also follows the change of the liquid level and drives the main shaft to rotate, and the angular displacement sensor of the meter head and the main shaft are axially connected to form a synchronous operation mechanism with the main shaft. Therefore, after the angular displacement sensor converts the rotation angle signal of the main shaft into an electrical signal, the electronic circuit inside the meter converts this signal into a standard 4-20mA current signal proportional to the liquid level change.

Specification

| Measuring Function | Liquid level |

| Measuring Range | Large angle type 450~1600mm |

| Small angle type 380~1200mm | |

| Measurement Accuracy | 1.5%ES |

| Supply Voltage | 24V/DC (12.7-27.2V) |

| Output Signal | 4~20mA/DC |

| On-site Indication | Multi-parameter LCD display (intelligent) |

| 0~100% (4~20mA) moving coil type (analog type) | |

| Explosion-proof Mark | Flameproof ExdlICT4 |

| Intrinsically Safe ExiaIICT4 | |

| Protection Class | IP67 |

| Ambient Temperature | -20~60°C |

| Ambient Humidity | W95% |

| Medium Temperature | -40~225°C (without heat sink) |

| 225~450°C (with heat sink) | |

| Medium Density | >0.55g/cm3 |

| Working Pressure | 2.5, 4.0, 6.4MPa |

| Connection Flange | Standard type DN250 PN according to the selected grade JB/T82.2-94 (raised surface) |

| Special type DN200 PN according to the selected grade JB/T82.2-94 (convex surface) | |

| Outlet | M20X1.5 (internal thread) Electrical enclosure: Die-cast aluminum alloy powder coating. |

| Float Maximum Running Angle | Small angle type: 35° |

| Large angle type: 80° | |

| Wetted Part Material | Standard ICr18Ni9Ti; |

| Special type 316L, 316o | |

Float Level Transmitter Test

Installation and Precautions

The transmitter is directly installed on the side wall of the container through the connecting flange. The installation position and direction should take into account the convenience of operation, observation, inspection and maintenance. There are two installation methods: left-side installation and right-side installation. Unless there are instructions when ordering, they are installed on the right side.

Before installation, the connection between the float ball, float rod, balance rod and sensor and the main shaft should be fastened to prevent loosening and falling off. After all parts are connected, shake the float rod up and down to check whether the rotating parts run flexibly and synchronously. Remember not to shake the balance rod to check.

After the installation is completed, the pressure test should be carried out together with the container to check the mechanical strength and sealing performance.

When transporting or installing, never throw, drop or knock the level gauge; when transporting, it should be packed according to the packing method provided by the manufacturer.

The safety barrier used in the intrinsically safe type shall comply with the "Precautions for Safe Use of Intrinsically Safe Displacer Level Gauge" in the technical parameters of this manual.

In normal use, when debugging is required, the analog watch only needs to open the front cover of the display watch; the smart model only needs to open the front or back cover of the display watch. When operating, the power should be cut off first. During the disassembly and assembly process, attention should be paid to the explosion-proof surface of the explosion-proof product to avoid damage, and the fasteners should be tightened as much as possible to ensure good sealing performance.