Vacorda High Temperature Tube Liquid Water Dispenser Level Sensor

Measuring Range 300, 500, 800, 1100, 1400,1700,2000mm(custom made)

Indicate Mode single color, bicolor(red as vapor phases, green as liquid)

Material carbon steel, 304,316L, 1Cr18Ni9Ti, 0Cr18Ni9, 304 with PTFE lining

Nominal Pressure PN6-PN100(×0.1MPa), 304 +PTFE≤PN40, PP≤100°C

Process Flange DN20/RF HG/T 20592-09

The Heat Steam Interface ZG1/2"male screw thread

The Heat Steam Pressure ≤1.0Mpa

Eclectic Heating self-limiting temperature heating (unnecessary for anticorrosive type)

Steel Ball Self-closing Pressure ≥0.3Mpa

Power Supply 24V DC, 36V AC

Environment Temperature --70℃~+450℃

Keywords:

Product Details

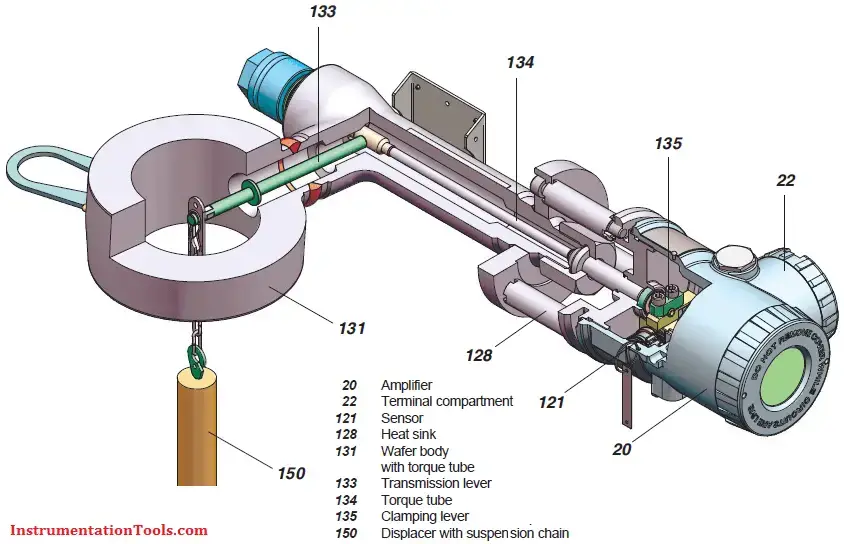

The buoyancy force of the displacer is transferred via transmission lever and torque tube to operating rod of the sensor, where it acts on free end of sensor element.Four thin film metal strain gauge elements are sputtered onto sensor element, which change their resistance in the ratio of the tensile or pressure tension. These four thin film metal strain gauge elements are connected as a Wheatstone full bridge supplied from amplifier.

The voltage at the diagonal bridge section which is proportional to the effective weight is fed to the electronic amplifier as an input signal. This voltage is converted via the electronic amplifier into the 4 to 20 mA or digital two-wire output signal. The amplifier is supplied by the signal current circuit in two wire mode.

HKD 3000 Series Intelligent Float Level Transmitter is a level transmitter developed by introducing foreign technology. It consists of an intelligent processing unit, a measurement room, an internal buoy and a torque tube assembly. Changes in the liquid level of the measured medium cause changes in the internal buoyancy. The changing force causes the resultant force of the torsion tube to change and is transmitted to the torsion tube assembly, so that the torsion tube and the mandrel are deflected synchronously. The detection device on the shaft detects the displacement of the deflection, and the intelligent processing unit converts the displacement into a 4-20 mA signal output. The intelligent processing unit can detect changes in the ambient temperature and linearly compensate the output signal. It can also compensate for changes in liquid density caused by process temperature changes.

HKD3000 series intelligent liquid level (boundary) liquid level transmitter provides standard 4 ~ 20mA current signal output, on-site LCD liquid crystal display, and can provide communication functions such as HART.

Steam Boiler Level Gauge Technical Parameters

|

Recommended center-center distance: |

300, 500, 800, 1100, 1400,1700,2000mm(custom made) |

|

Indicate mode: |

single color, bicolor(red as vapor phases, green as liquid) |

|

Material: |

carbon steel, 304,316L, 1Cr18Ni9Ti, 0Cr18Ni9, 304 with PTFE lining |

|

Nominal pressure: |

PN6-PN100(×0.1MPa) |

|

304 +PTFE≤PN40 |

|

|

PP≤100°C |

|

|

Process flange: |

DN20/RF HG/T 20592-09 |

|

The heat steam interface: |

ZG1/2"male screw thread |

|

The heat steam pressure: |

≤1.0Mpa |

|

Eclectic heating: |

self-limiting temperature heating (unnecessary for anticorrosive type) |

|

Steel ball self-closing pressure: |

≥0.3Mpa |

|

Power supply: |

24V DC, 36V AC |

|

Environment temperature: |

--70℃~+450℃ |

Sichuan VACORDA Instrument Manufacturing Co., Ltd.

E-mail: sales@vacorda.com

Tel: 0086-028-87362258

7X24 hours online

Address: Guanghua Rd, Qingyang Dist, Chengdu, Sichuan Province, China

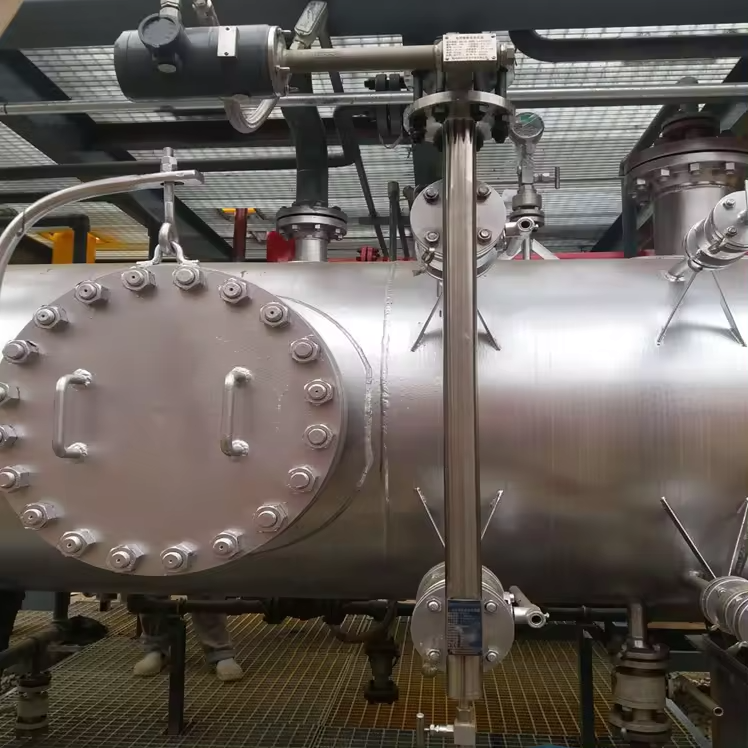

Related Application

Hot Products